Mitutoyo Mach KoGaMe

3D in process measurement in automated cells

MACH KoGaMe is the ideal solution for automated cells in workshop environments

Guarantees a maximum permissible error of

MPEE=(2.4 + 5.7L/1000)μm

Speed, reliability and universality for your production control

Ideal in process 3D measurement solution: MACH KoGaMe

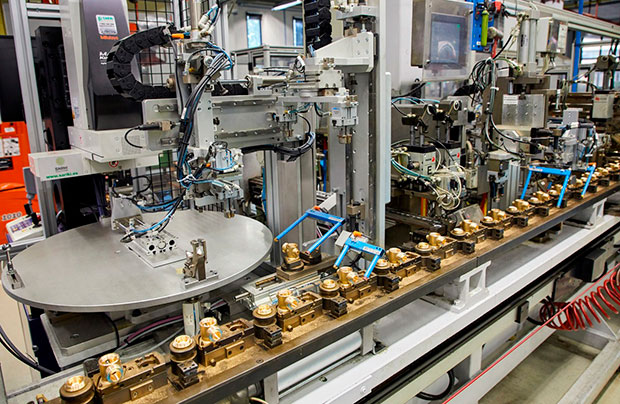

This is a measuring machine for workshop environment (10 ~ 35 °C) with compact structure 376x432x748mm. It can be used as an individual inspection solution in the quality laboratory, it can be implemented close to the line by a manual piece loading system for the operator or inline using an automated loading system with robot for a close circuit automated process control.

It has a small size without losing the capabilities of a three-dimensional machine. It can be mounted on any rigid frame, including machine tools. Ideal for inspection of geometric entities with both continuous and point-to-point measurement probes. Probe system PH6, TP200 and SP25

It offers flexibility, if production requirements change, you can move the MACH KoGaMe and reconfigure the machine to accept different references and even use it in the measurement laboratory. It has an I/O connection system, connection interface with robots, conveyor lines and sensors, which facilitates its integration into manufacturing cells and automated factories.

Take measurements at high speed. Maximum speed on 1 axis 200mm/s, maximum speed on 3 axes 340mm/s and speed of measurement 0-15mm/sec. Acceleration 0.68G.

Measuring range up to 120mm.

Related Products and Services

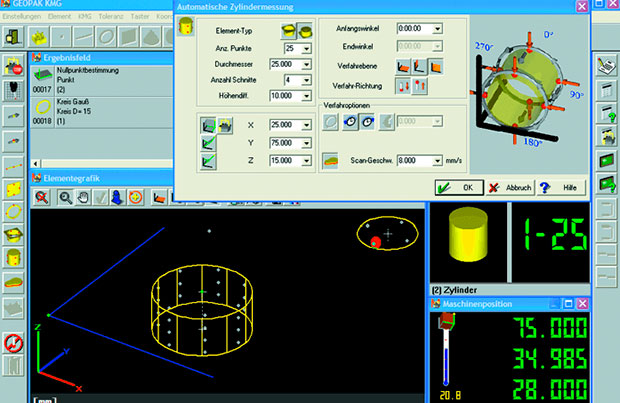

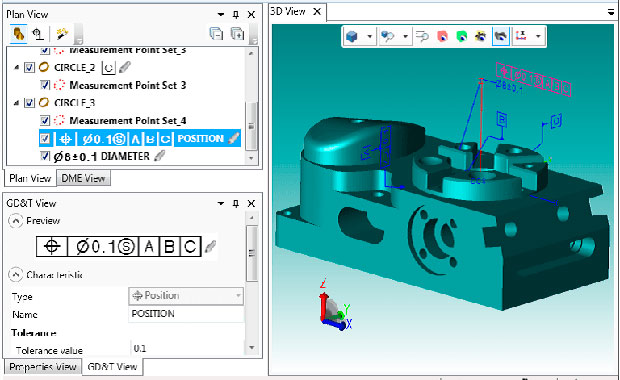

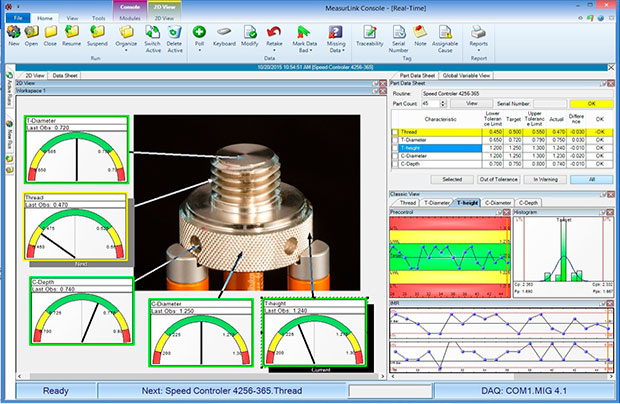

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

Measurement of automotive parts and bar turning (engines, pistons, filter assemblies, brake components, fuel lines, bearings, piston rods, wheel axles, throttle body), energy sector parts measurement (flanges, pumps, accessories, housing), aerospace sector (impellers, pumps ...), medical sector (implants, surgical instruments ...), parts with injection processes (molds, housings, bottles, caps, moldings ...)

Measuring probes

You will have a versatile and flexible system, which you can incorporate the following probes.

TP 200

SP25M

Custom Solution

Our engineering department can customize and integrate the MACH KoGaMe coordinate measuring machine according to your requirements. Tell us what your challenge is and Sariki will advise you to identify which is the best solution for your specific case.

LOADING SYSTEM

You can incorporate manual, semi-automatic and automatic loading systems into the equipment

CABIN SYSTEM

We identify the cabin system that best suits your application

INTERACTION WITH PRODUCTION MANAGEMENT SYSTEMS

We guarantee 100% traceability of the process by integrating the CMM data with your MES/ERP system

CUSTOM PROGRAMMING

We have experienced staff in programming and measurement for the realization and implementation of measurement part-programs

TURNKEY PROJECT

If you are looking for a turnkey project you can trust on us. We work with you from the conception of the idea and definition of project conditions, prior acceptance, installation in your company, user training and technical assistance and support throughout the life of the project.

We face integration projects from a holistic view of inspection guidelines and are committed to comply hybridization technologies. We are able to develop an inspection solution that combines different technologies: three-dimensional machine, roughness, vision, etc.

Technical specifications

Measuring range

X 120mm

Y 120mm

Z 80mm

Accuracy

(2.4 + 5.7L/1000)µm

from 19ºC to 21ºC

Resolution

0,0002mm

Driving speed

Up to 340mm/s

Driving aceleration

Up to 6.750 mm/s2

Temperature range

From 10ºC to 35ºC

Machine mass

28 Kg.