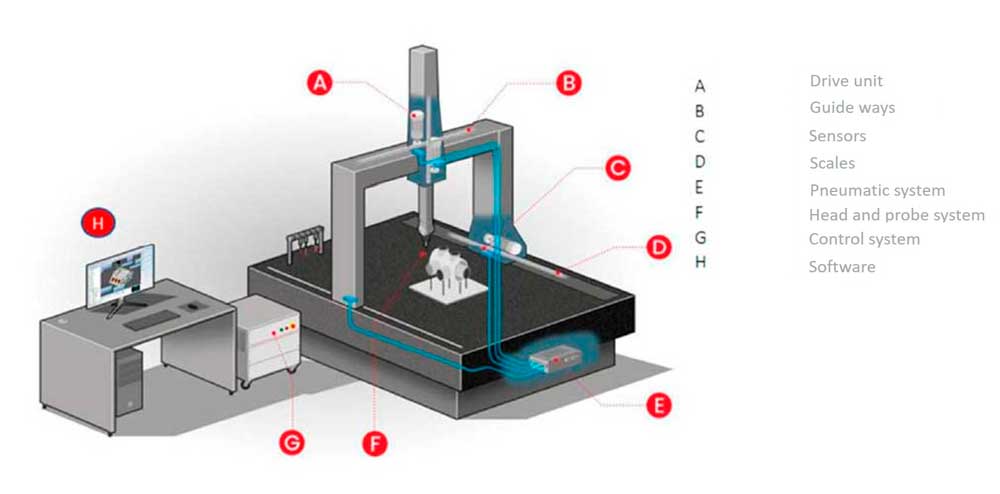

Retrofit of CMM to optimize productivity

The retrofit consists of updating the electronics and measurement software of any CMM on the market.

It normally emerges as a reliable alternative for customers who want to keep their 3D measurement equipment up to date without the need to change hardware.

It is possible to update any CMM, be it arm or bridge structure, manual or CNC, and from all manufacturers.

The retrofit is an extraordinary solution for those cases in which a CMM has hardware in good condition and whose electronic control or software has not evolved, ceasing to be able to respond to current measurement needs.

Retrofit strengths

The replacement of the CMM control allows optimizing the performance of the system, as well as opening the possibility of integrating other measurement technologies.

- Scanner laser for 3D scanning

- Continuous measurement probes

The software update opens up the possibility of direct connection to a large number of multi-brand CMM controllers and offers advanced metrology functionalities that will help optimize dimensional inspection.

Retrofit types

- From software-only updates to complete machinery rebuilds.

- Replace, modernize and adjust the mechanical and pneumatic elements, which are essential for the good geometry of the CMM.

- Complete rewiring of the CMM. Replacement of scales and probes.

- Check and adjust servo motors and CNC controllers.

- Update and enhance the probing system, with continuous scanning technology and/or 3D laser scanner.

We use these electronics:

We use these softwares:

Retrofit benefits

Extending the useful life of your CMM

Converting your analog equipment into a digital machine

Possibility of adding all kinds of new technologies (probing sensors, laser scanner...)

Economic savings compared to the acquisition of a new CMM

Improved productivity and speed of measurement (Up to 40% time savings)

Improved reporting, connectivity and format sharing capabilities

Benefit in financial aid for circular economy, equipment reconversion

Volumetric compensation of the entire machine volume. Measurement homogeneity

Personalized maintenance plans with full or partial assistance

Enac calibration

Greater knowledge of your parts at dimensional level

Take another step towards industry 4.0 with your system

If you need more personalized information or want us to send you a quote, you can fill out the following contact form.