Inicio » SARIKI will take part in the BIEMH’s most ambitious edition

UNCETA GROUP will attend the International Machine-Tool Biennial – BIEMH from June 13th to 17th. Visit us at HALL 3 – C31!

After four years of standstill, this is an edition marked by the reunion.

The manufacturing industry is undergoing a transformation process towards digitalization of processes, in-line automation or the incorporation of advanced manufacturing systems, and from UNCETA GROUP we want to show you the best Industry 4.0 focused solutions.

To this aim, we have made a strong bet and we will present many innovations in the automation and dimensional control’s digitalization fields. Keep on reading, and get to know the proposals that best fit your company’s needs:

SMART FACTORY INSPECTION CELL

We will present for the first time in Spain an automated cell specifically designed for the smart and connected factory. The cell integrates different Mitutoyo measurement equipment (1 MiStar 555 compact CMM, 1 MiSCAN 302 latest generation vision measuring machine, 1 Formtracer Avant FTA-H4D44000 for contour and roughness measurement, 1 HR-620B hardness tester, 1 Tag lens sensor), 3 FANUC robots for automatic part’s loading and unloading, as well as a conveyor system for part’s transportation.

The smart factory inspection cell is developed with RFID laser sensors for part detection, proximity sensors to detect if the pallet is empty or not, as well as sensor to check the machine home positions. We will show the IoT platform developed for monitoring the cell.

SARIKI SOLUTIONS: SK/solutions

In SARIKI we have bet on developing inprocess control-oriented metrology solutions. This brings a change in our business model, where we not only provide our engineering capacity to develop turnkey projects, but we have focused and developed a new strategy to offer the market our own SK/solutions.

We will present 2 of our own solutions for the first time:

· Flexible in-line measurement

This solution developed by Ekide and Sariki, with the collaboration of Vicomtech technology center, ensures 100% inspection of high cadence manufactured parts.

What’s more, it adjusts to the production line cycle, and allows the processing of large volumes of information through our own SK/inspect software. The solution is designed to ensure the inspection’s quality working in high demanding production environments.

SK/cell is our advanced in-line solution based on the integration of a high-speed structured light scanner on a flexible robot.

The solution’s main application is the contactless in-line inspection of automotive and aerospace parts. Our software SK/inspect enables faster measurement, processing, and information acquisition, and it offers an automated 3D measurement experience.

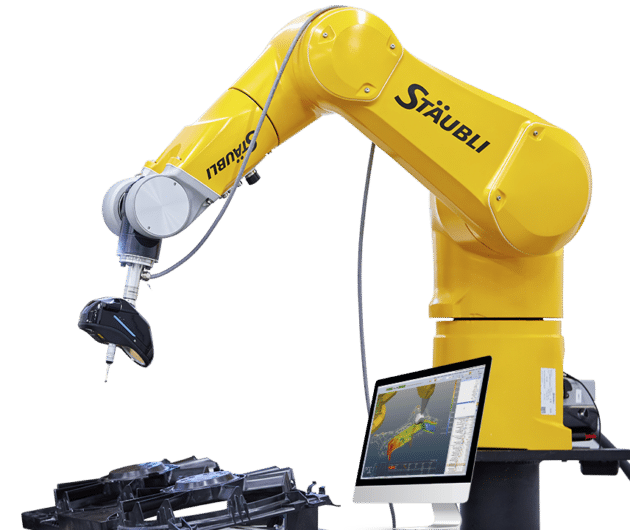

We will present the CMRobot automated solution, a solution that is easy to set up, use and maintain. It allows you to perform measurements quickly and generate data that can be easily integrated into the workflow. Its main application is the in-line inspection of automotive and aerospace parts, and thanks to the 3D laser scanner technology, it guarantees a non-contact 3D measurement without the need for a tracking system. The CMRobot combines:

Robot from the manufacturer Stäubli.

Kreon Zephyr II Blue scanner with optical and tactile sensor.

Software metrolog X4 i-robot.

Bridge type CMMs are always a safe bet: speed, accuracy, and flexibility for your quality’s assurance. We will present exclusively for Spain Mitutoyo’s new Crysta Apex V series, with the new MCosmos V5.0 software platform and MiCAT for offline programming.

The entire Crysta Apex V series is equipped by the SMS (Smart Measuring System). This Smart Measuring System allows online monitoring of measurement precision equipment. We will show the Status Monitor application that allows remote monitoring of the operating status of the measuring equipment.

ViciVision machines allow you to automate the dimensional control of your turned and ground parts directly in production. You can measure your parts directly on the workshop without interrupting production.

We will present the ViciVision M609 Techno machine, on which we will measure a camshaft by combining 2 technologies: on the one hand, non-contact optical technology, and, on the other hand, touch probe technology.

EASY TOM S INDUSTRIAL CT MACHINE

We will present RX SOLUTION’s Easy Tom S machine. It is a Computed Tomography (CT) system that uses X-Ray technology to identify defects and verify part’s internal and external geometries. Industrial Computed Tomography is a non-destructive image capture process, and thanks to that, the presence of porosity or internal defects can be detected.

Its main applications are defect and thickness analysis, dimensional inspection or comparison against CAD in sectors such as automotive, aerospace or medical. It is also ideal for the dimensional control of additive manufactured parts.

The Polyrix Polyscan technology will be presented for the first time in Spain, the ideal solution for 3D scanning of large parts. It is a 3D structured light scanner that allows you to control your parts in a simple, fast and reliable way. Thanks to this solution, you will be able to automate 3D inspection processes and guarantee a full part coverage in a single scan.

The typical applications for this technology are, above all, dimensional inspection and the inspection of components, tools and models. An in-line fully automated and integrated scanning.

The C500 scanner is a structured light 3D scanner ideal for small and medium-sized parts scanning. During the exhibition we will present an application with our SK/inspect software, where you will see a part’s digitalizing, a comparison against CAD and color mapping, as well as section dimensioning.

If you are thinking about taking a step and digitalizing your inspection process, do not miss this opportunity and come and see how easy it is to work with this equipment.

KREON ACE ARM WITH SKYLINE SCANNER

The Ace measuring arm is a portable and flexible 7-axis three-dimensional machine that allows you to perform measurements directly in production environments. You can use it both for quality control and prototyping.

We will present an application performing measurements with 3D laser scanning technology and probing technology, using Metrolog X4 software.

VIRTUAL TOUR OF OUR SERVICE AREAS

In UNCETA GROUP we offer a wide range of technological services to the market. In this biennial marked by the reunion, we have thought about bringing you closer to our facilities by using digital tools. Through virtual reality glasses, you will be able to walk along our measurement service center SARIKI PRECISION CENTER, our engineering and projects area, training room, as well as SARIKAL calibration laboratory. A unique experience!

Now that you know all the solutions and technologies we plan to surprise you with… Are you going to miss them?

Celebrate the BIEMH reunion with us and visit us at our Stand by registering here for free!

If you also want to be the first one to know about all the news and solutions in the dimensional metrology field, subscribe to our Newsletter!

Open House at Sariki Elgoibar

7 October, 2024

Success in our Technical Day on Weld Seam Inspection at the AIC

26 September, 2024

Sariki and Vicomtech present an innovative flexible and autonomous 3D scanning cell

25 September, 2024

SERVITIZA 4.0 Eco-innovation Project

24 September, 2024

RETROFIT Eco-innovation Project

20 September, 2024

Customer support in august 2024

22 July, 2024

Technical day: Automated In-Process Weld Seam Inspection

5 July, 2024

Changing Metrology Rules at BIEMH 2024

24 June, 2024

Sariki will change metrology rules at BIEMH24

8 May, 2024

Discover Onyx: Kreon’s state-of-the-art measuring arm

7 March, 2024