New Mitutoyo MCOSMOS 5 software platform

The Future of CNC CMM Data Processing

The well-known software suite, MCOSMOS, is the go-to data processor for Mitutoyo’s range of top-of-the-line CMMs. Made up of their extensive lineup of optional software applications, users have full support for a wide range of probes ready for any kind of workpiece.

Mitutoyo releases the newest platform of their advanced metrology suite for coordinate measuring machines. This software known as a standard throughout the world offers support in 37 different locations and in 12 different languages, making it obvious why engineers know and love it.

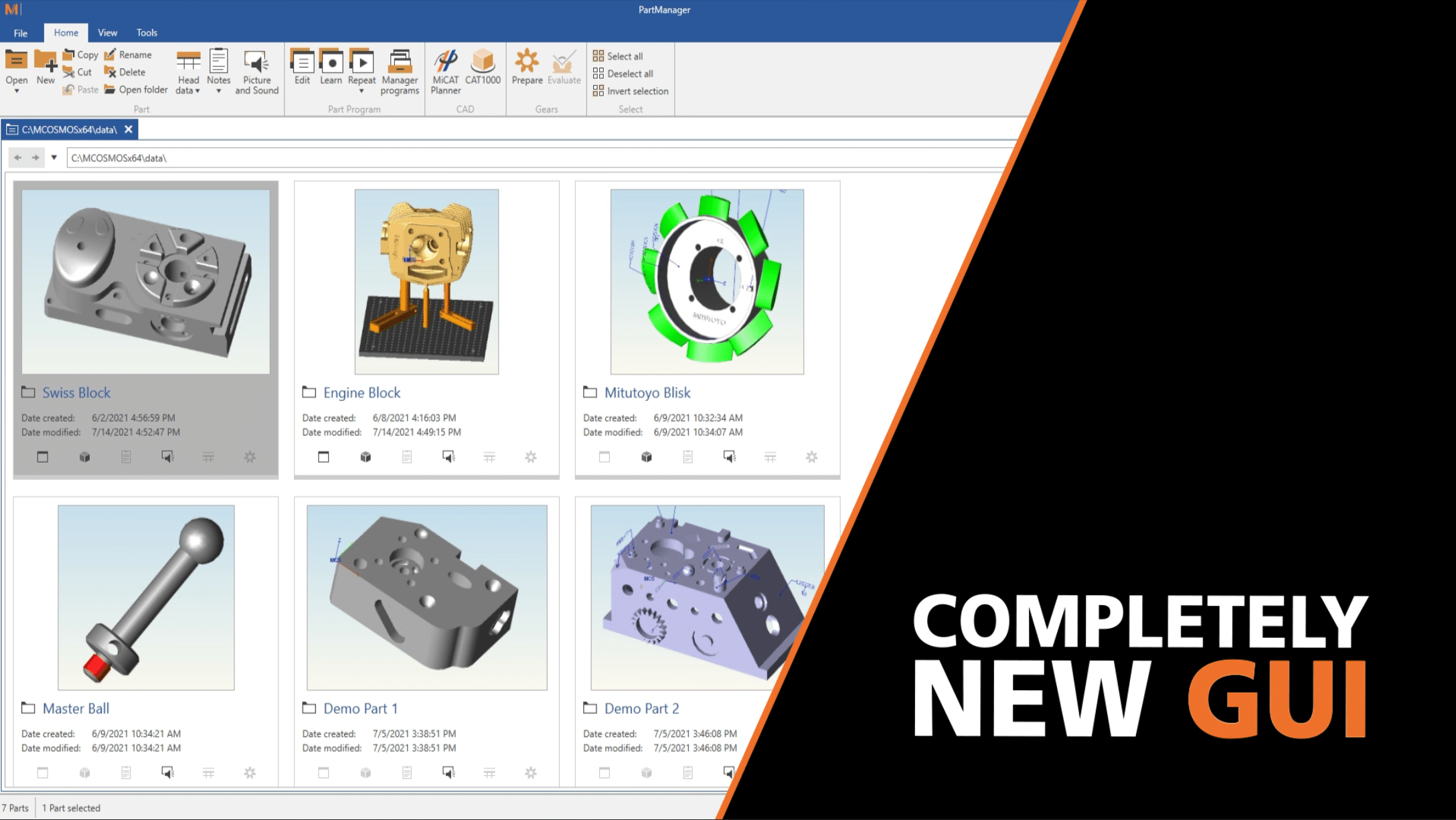

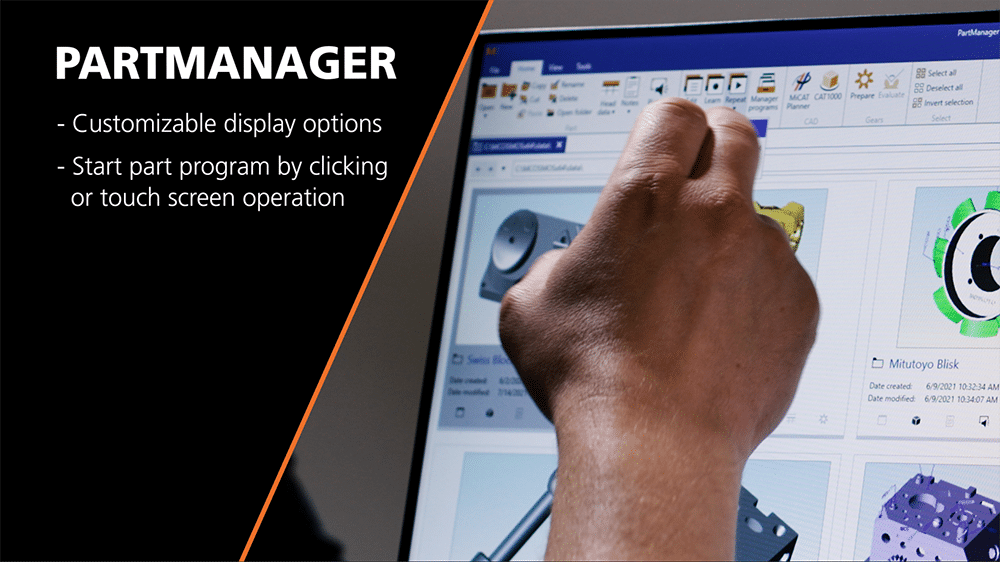

What distinguishes MCOSMOS 5 from its predecessor are the upgrades to its interface, functions, and performance. Most noticeable from launch is the new and simplified graphical user interface: The updates made to this are not only visually pleasing but also assist in improving the user experience, no matter their level of knowledge working with the tool. These changes include easy-to-use “ribbons” and a much-requested search function, assisting operators in finding specific sections of their measuring process for detailed reports.

Key features and capabilities of Mitutoyo’s MCOSMOS 5 software suite:

- New Graphical User Interface – Modelled with a modern design, this new GUI improves on the previous version with a simplified and attractive module display.

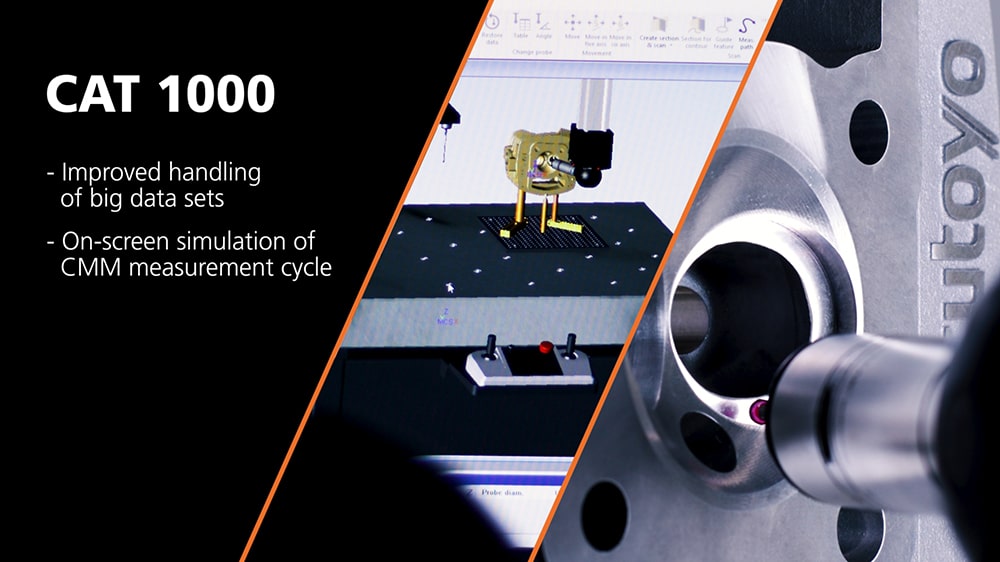

- Optimization for large CAD files – A large amount of progress has been made in Mitutoyo’s optimization for large CAD files over their previous versions of software, lowering process time and improving the overall operation of MCOSMOS.

- Element Finder – Designed to assist the user in their quest for specific programmed elements of their measuring processes, error corrections, and detailed reporting

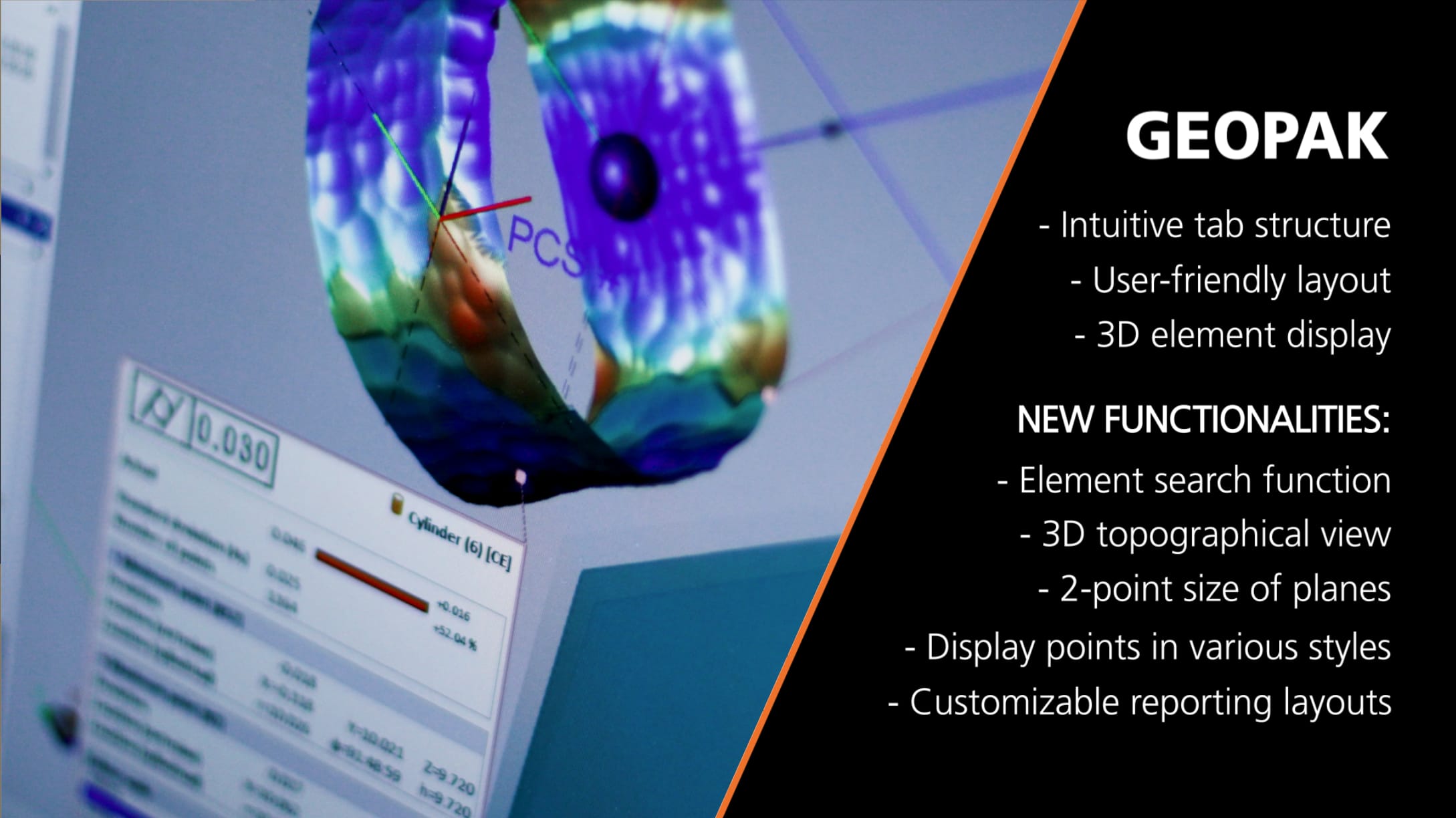

- 3D Topographical View – Added in this new version of MCOSMOS is the possibility of using a three-dimensional display of the geometry and microstructure of technical surfaces including visualization of tolerance zones, providing operators with a more detailed overview of their workpiece. This is especially handy when operators are utilizing non-contact measurement methods.

- GD&T reporting – With a new modern design template, tabular layout, and tolerance value graphics, this newly added feature is becoming a standard among inspection reports, making it easy to summarize the true positions and tolerancing of workpieces.

- Adjustable Ribbons – The selection menu will come in the form of “ribbons” which offer easy-to-use functions for operators such as resizeable icons, customizable sections, part lists, and a docking layout.

- Point Displays – These figures are placed with accurate 3D representations in thousands of points over your workpiece, and display tolerance indication based on their color. And to shorten render time, the ability to swap the points from 3D to 2D representation of the points is possible.

- Revision Management – Prevents use of non-validated programs, by not allowing restricted users or the measuring programs themselves run if any changes occur. Reports made using this function are also forgery-proof and are exported as pdf.

- Speed Up Execution – Deactivates unnecessary graphics during the process execution phase, saving resources to speed up part programs.

- Enhanced Mouse Operation – Modelled to be the same as in MiCAT Planner or other CAD operation software, everything can be controlled via the mouse as well as hotkeys for experienced users.

- Styli & Fixture Builder – Coming as a standard, the Styli & Fixture builder is provided with MCOSMOS 5, making it easier to build the correct styli or fixtures for your task.

- Quick Access Toolbar – A function that enables the operator to create a customized quick access bar that is independent of the standard ribbon structure for frequently used functions.

Still haven't upgraded to Mcosmos 5?

Request the update to the new MCOSMOS 5 platform through the form and we will advise you for free.