Héroux-Devtek Spain

La tecnología QS-L de Mitutoyo vuela alto de la mano de HÉROUX-DEVTEK SPAIN

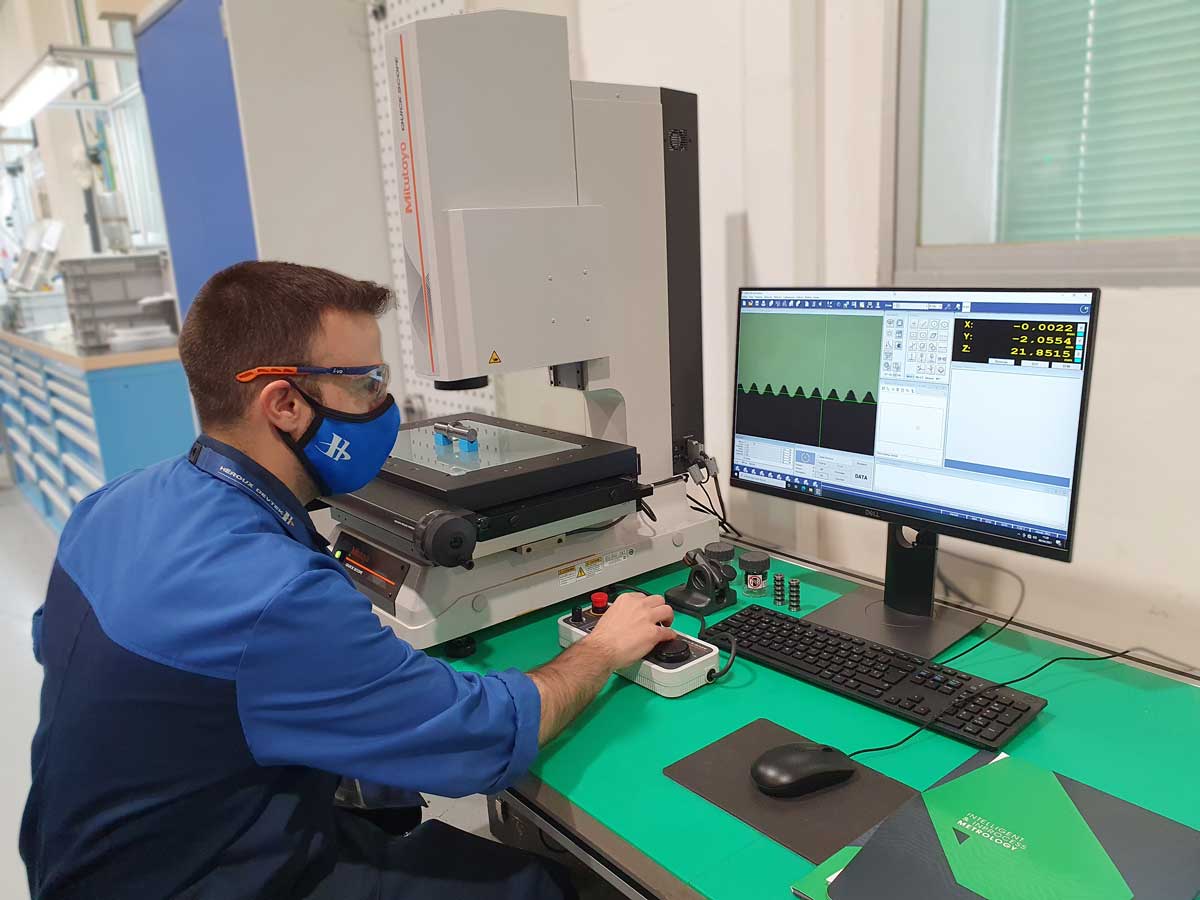

Tecnología: Mitutoyo Quick Scope

Sector: Aeronáutico

Héroux-Devtek Spain es una empresa internacional especializada en el diseño, desarrollo, fabricación, reparación y revisión de trenes de aterrizaje, sistemas de actuación y componentes para el mercado aeroespacial.

La seguridad industrial es un aspecto clave en el desarrollo y certificación de equipos aeronáuticos y para ello utilizan el más avanzado nivel tecnológico. Trabajan con una gran variedad de producto aeronáutico lo cual requiere la realización de múltiples validaciones por parte del equipo de calidad.

Dentro del departamento de calidad, utilizaban varios sistemas de visión complementarios. Esta situación, aunque no afectaba directamente a los niveles de calidad, si lo hacía en la productividad, la cual se veía resentida al requerir mayores tiempos de medición.

Sariki participó en el proceso de selección de proveedor con el que invertirían en un nuevo equipo de medición por visión.

Dispone de:

- Mesa de 400x200 mm.

- Eje Z CNC con función de enfoque automático.

- Power-zoom 8x programable.

- Zoom óptico y digital.

- Cámara en color CCD de alta resolución.

- Iluminación de la mesa, coaxial y anillo luminoso.

- Tecnología “One Click Tool” para una óptima detección de bordes.

- Software Scanpak para analizar perfiles en 2D.

La compañía BOEING ha adjudicado a Héroux-Devtek Spain un contrato para la fabricación de componentes de actuación para varias de sus plataformas comerciales.

El alcance del contrato incluye la producción y mantenimiento de actuadores hidráulicos de los sistemas de trenes de aterrizaje para las aeronaves 787, 777 777X y B767 (en versiones carguero y “Tanker”) y para repuestos del mítico B747.

Este es el mayor acuerdo de suministro de actuadores realizado por el grupo Héroux-Devtek Spain desde que el grupo canadiense adquiriera la Compañía Española de Sistemas Aeronáuticos SAU (“CESA”) en octubre de 2018.

La máquina de medición por visión QS-L de Mitutoyo se está utilizando en la industrialización de nuevas piezas e inspección de primeros artículos de sistemas de actuación de trenes de aterrizaje de este gran proyecto. Se trata de piezas de gran complejidad y coste. En este proceso es donde sacan al equipo su máximo rendimiento ya que disponen de una gran variedad de piezas, que requieren gran variedad de características geométricas a medir. Gracias al equipo QS-L realizan la verificación con mayor precisión y rapidez y esto les supone un ahorro de costes importante. El equipo también se utiliza de forma esporádica en procesos de reparación.

El departamento de calidad cuenta con 4 verificadores que recibieron formación y que utilizan el equipo QS-L de forma habitual.