Industrial metrology: the key to reducing costs.

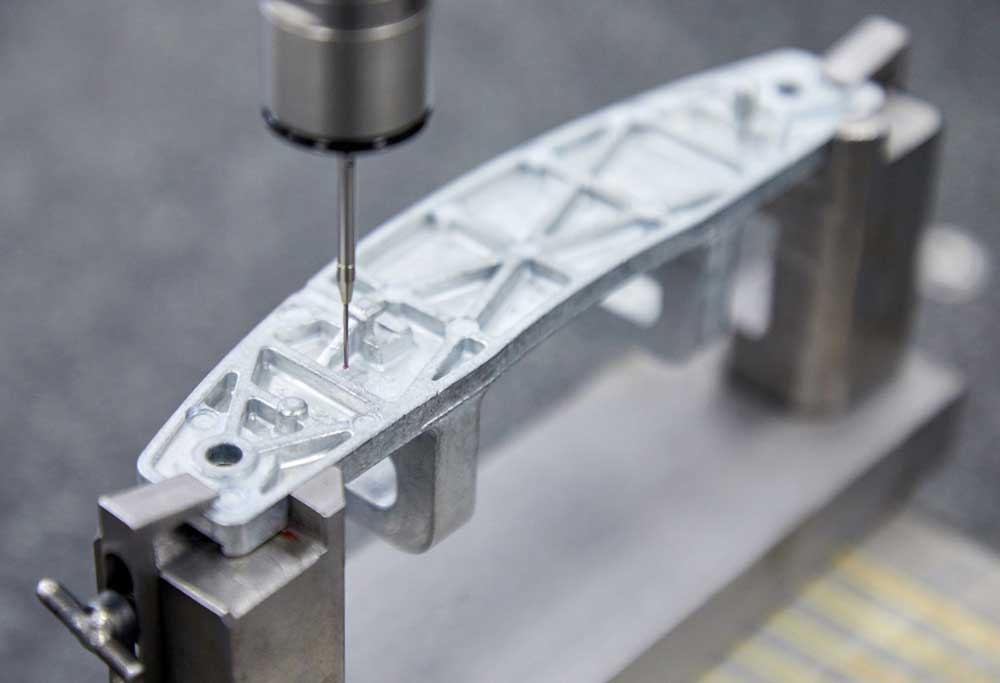

In order to ensure quality and part’s results, measurements are an essential part of the process, especially in the industrial sector, where controlling these parameters may lead to the satisfaction, or not, of our customers.

In general terms, industrial metrology is the science of measurement that ensures that the instruments used in industry work properly. A batch that does not fit your customer’s standards means a cost to your company, due to the rejections and returns it generates. Therefore, accuracy in measurements is crucial to ensure your produced part’s quality.

Applying industrial metrology in your processes brings many advantages to your company.

- When increasing your product’s quality, you will reduce the number of returns due to non-conformities and, therefore, avoid return costs.

- It promotes competitivity in the market by controlling part’s quality and, therefore, making the industry equipped with accurate measuring instruments.

- There is an international standardization thanks to the harmonized system common to all countries.

- You will be able to perform comparatives between two different industrial parts and detect and study defects accurately.

- It allows the automation of processes and the optimization of the metrological inspection tasks. This makes the results much more accurate, increasing product’s quality.

- It ensures metrological traceability that allows you to achieve high reliability and precision in industrial measurement.

Nowadays, industrial metrology plays a fundamental role in industry.

The perception towards dimensional control changed many years ago. For a long time, quality control has been considered a cost that does not bring value to the final customer, and it was tried to be reduced to a minimum. Today, this is unthinkable: dimensional control brings, among other things, differentiation from competitors due to the increase of brand recognition and quality.

After all, if a company repeatedly delivers defective parts, where is the confidence in that supplier? If we want to position as referents in our customer’s minds, we cannot afford to trip over the same stone every time.

The cost of a return is not only monetary: in addition to the fact that it can exceed the product’s value, it damages the company’s image and reduces confidence, which can cause us to lose a client or even future customers.

Industry 4.0 has made metrology adapt to the Smart Factory.

In this context, it is worth mentioning that quality control has evolved over time: identifying defect is important, yes. But the trend shows that errors must be avoided at their origin in production.

Companies no longer think about having innumerable measuring instruments in a metrology room, that create bottlenecks and the need to train their workers in different technologies, with the time and cost this implies.

By integrating industrial metrology in your manufacturing process, performing dimensional verification at each phase of the process, you are with no doubt advancing in the Smart Factory concept. This way, you will be able to ensure processes adjusting to the production cycle times with interconnected measuring equipment.

Nowadays, dimensional measurements need to directly support production, by collecting data automatically to help anticipating errors and, in case of any, correcting the process.

In this demanding environment, it is essential to count on precise instrumentation that meets the production process’ requirements, such as speed and the environment in which it operates. The objectivity of those instruments is also a factor to take into consideration when making an investment, in addition to the usability and comfort.

In Metrologia Sariki we develop flexible dimensional metrology solutions for the Smart Factory.

We are a company with more than 35 years of experience in the industrial metrology sector, and we are able to adapt to any need, both in the supply of equipment and offering a complete measurement service.

Do you have any unanswered questions?