100% in line measurement

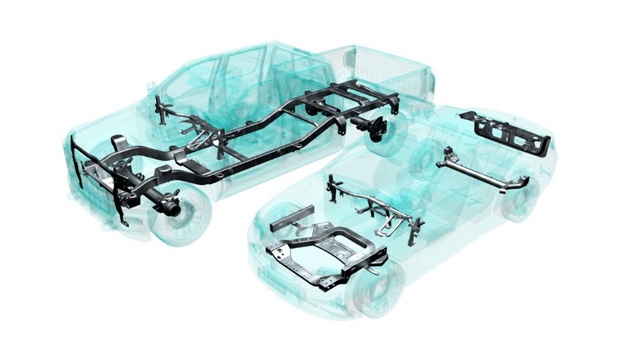

Te proponemos una solución integral para inspección 100% en la línea de componentes de fundición, incluyendo travesaños longitudinales, módulos frontales (FEC, GOR), puertas traseras, componentes de la transmisión, módulos de la parte inferior de la carrocería e incluso chasis de escalera completos.

Sariki es distribuidor oficial de MAPVISION para España

Tecnología para medir 100% en línea

Sabemos que gestionas un proceso de producción complejo que implica cierto grado de inestabilidad, pero, sin embargo, te exigen una calidad del 100% en tus entregas. Para gestionar el SPC, es necesario que tus procesos se ajusten de forma que cumplan con los estándares de tu cliente. Sin embargo, el SPC te proporciona muy pocos datos de la producción pasado un margen significativo de tiempo. Puede que la calidad de tu producción parezca perfecta, pero no es así.

Tener acceso de forma inmediata a datos de medición extensos y fiables cambiará todo esto.

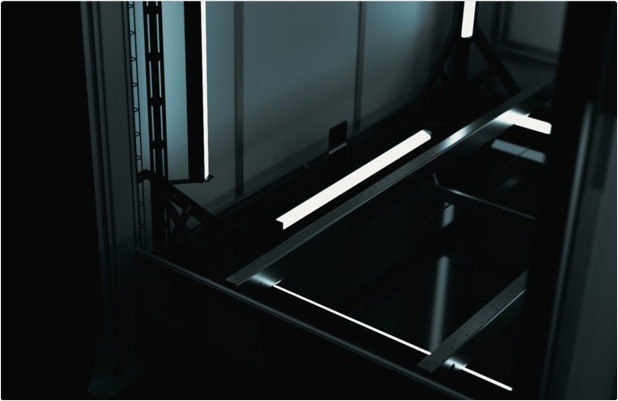

Te proponemos una tecnología novedosa, completamente digital (sin imprecisiones ni fallos mecánicos), multicámara y capaz de medir todas las características de todas las piezas en la línea dentro del tiempo del ciclo.

Somos capaces de medir cientos de puntos 3D (x,y,z) en menos de 30 segundos y al mismo tiempo realizamos inspección visual de forma automática para detectar presencia/ausencia de elementos (tuercas soldables, pernos soldables, etc..)

Cada punto de medición se observa con varias cámaras. Esto permite al sistema garantizar la precisión de cada medición verificando la homogeneidad de las imágenes. Además, garantizamos normalmente +/- 0,02 mm con piezas reales de producción.

Beneficios

Obtener datos útiles para mejorar la calidad de la geometría desde el día uno de la preproducción

Medir cada característica de cada pieza

Usar las imágenes de medición para identificar claramente los defectos

Realizar una inspección final automática del 100%

Hacer ajustes siempre que lo necesites

Controlar y optimizar tu proceso de forma eficaz

Aumentar la calidad de la producción

Solucionar problemas en tiempo real teniendo un verdadero conocimiento de dónde está el origen

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuales son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología.

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras soluciones de metrología para inspección 100% en la línea

Para componentes de carrocería y transmisión y chasis compactos, tales como brazos de arrastre, travesaños longitudinales y componentes del eje.

Caso de éxito

Grupo Gestamp realiza el control de proceso de travesaños del salpicadero y bastidores en todo el mundo con esta tecnología (Reino Unido, Alemania, EE. UU, China, Hungría, España y República Checa). Dispone de 50 instalaciones para controlar el proceso en su sistema de producción.