Specific Solutions

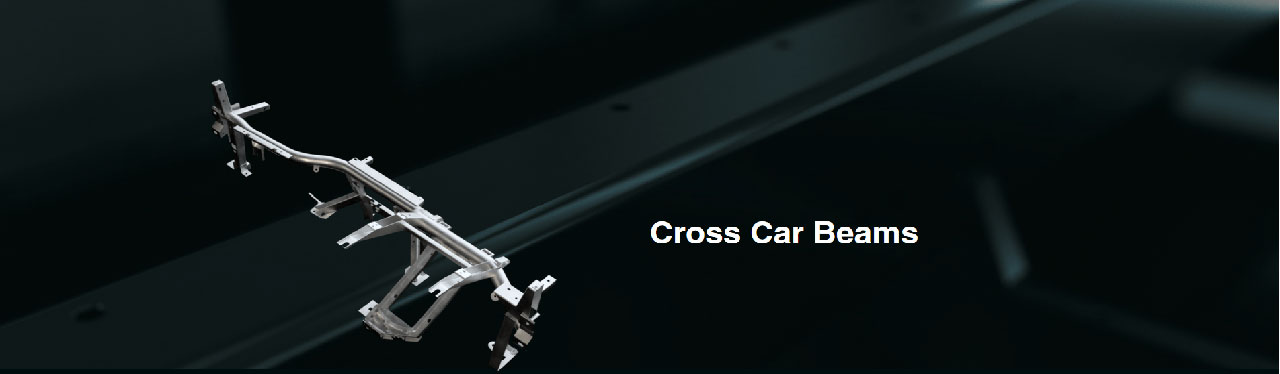

Mapvision 100% in process solutions help you take full control of your component production. Our solutions are used in the production of a wide range of welded and cast components, including side beams, front end modules (FEC, GOR), hatches, axle components, underbody modules and even entire ladder frames.

Measurement

- Measure every feature within 30 seconds – with no technical limit to the number of features you measure

- Measure feature locations in 3D (x,y,z)

- Calculate all distances, angles, etc..

- Use 100% in-line data to accurately adjust your line

- Get usable data for improving geometric quality from day one of pre-production

- Double shuttle allows parallel inspection of products from two different lines

Component Checks

- Automated component presence checks

- Component checks, e.g. weld nut presence and clip nut orientation

- No significant increase in inspection time

Measurement

- Measure every feature within 30 seconds – with no technical limit to the number of features you measure.

- Measure feature locations in 3D (x,y,z)

- Calculate all distances, angles, etc.

- Use 100% in-line data to accurately adjust your line

- Get usable data for improving geometric quality from day one of pre-production

Virtual Clamp (Exclusive to Mapvision)

- Collect both clamped and unclamped measurement results for a full picture of your subframes.

- No need for a mechanical clamp

- No hardware-related problems

- No maintenance of moving components

- Field-tested, ideal for subframes

Component Checks

- Automated component presence checks

- Presence checks for weld nuts, weld studs, etc.

- No significant increase in inspection time

Measurement

- Measure every feature within 30 seconds – with no technical limit to the number of features you measure.

- Measure feature locations in 3D (x,y,z)

- Calculate all distances, angles, etc.

- Use 100% in-line data to accurately adjust your line

- Get usable data for improving geometric quality from day one of pre-production

- Camber and toe angle measurement

Component Checks

- Automated component presence checks

- Component checks, e.g. weld nut presence and clip nut orientation

- No significant increase in inspection time