CNC measurement

Te proponemos una solución universal de inspección para verificar piezas del sector automoción, aeronáutico, salud, bienes de equipo, máquina herramienta, consumo…etc.

Esta tecnología es adecuada para la inspección dimensional de pieza mecanizada, estampación, inyección de plástico/aluminio, álabes de turbina, engranajes, moldes y matrices…etc.

Sariki es distribuidor oficial de MITUTOYO para España

Tecnología universal para garantizar la calidad de tus componentes

La tecnología de medición por coordenadas permite el aseguramiento de la calidad de tus piezas de forma precisa, flexible y a alta velocidad.

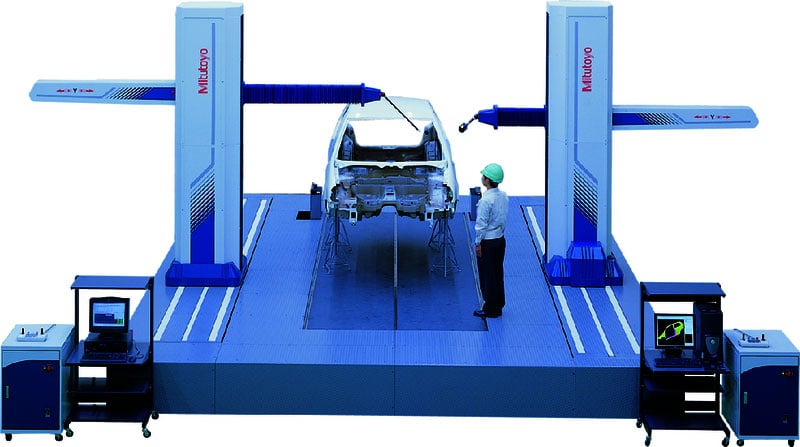

Las máquinas tridimensionales de tipo puente ofrecen especificaciones de máquina de alta precisión gracias a su construcción con materiales de bajo porcentaje de dilatación y alta resistencia. Esta tecnología además garantiza unos resultados independientes de la habilidad mejor o peor de cada operario.

Incrementan la capacidad de inspección.

Gracias al software que incluye la máquina podrás automatizar las mediciones y añadir utillajes de fijación que te permitirán medir más piezas en menos tiempo.

Son sistemas perfectamente equilibrados a los que puedes incorporar diferentes sondas y combinarlas de forma automática durante un mismo ciclo de medición.

Beneficios

Aumentar la calidad de la producción

Controlar y optimizar tu proceso de forma eficaz

Obtener datos útiles para mejorar la calidad de la geometría desde el día uno

Eliminar la influencia del operador en el resultado final de la medida

Medir entidades geométricas y conocer las desviaciones de piezas con forma simple o compleja

Mejorar el tratamiento estadístico de los resultados obtenidos

Realizar una inspección final automática de la pieza

Solucionar problemas teniendo un verdadero conocimiento de dónde está el origen

Beneficios

Aumentar la calidad de la producción

Controlar y optimizar tu proceso de forma eficaz

Obtener datos útiles para mejorar la calidad de la geometría desde el día uno

Eliminar la influencia del operador en el resultado final de la medida

Medir entidades geométricas y conocer las desviaciones de piezas con forma simple o compleja

Mejorar el tratamiento estadístico de los resultados obtenidos

Realizar una inspección final automática de la pieza

Solucionar problemas teniendo un verdadero conocimiento de dónde está el origen

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras soluciones de medición 3D

Crysta Apex S permite el aseguramiento de la calidad de tus piezas de forma precisa, flexible y a alta velocidad

La gama de máquinas STRATO Apex es el impulso que necesitas para aumentar la calidad de tus productos.

Las máquinas LEGEX te ofrecen figuras de precisión líderes en el mundo para realizar los trabajos más exigentes.

Máquinas diseñadas para la medición de componentes grandes y pesados.

Caso de éxito

DISPRE, especializada en el diseño y fabricación de utillajes y máquinas de control y producción a medida, ha incorporado recientemente a su proceso productivo una máquina de medición tridimensional Strato Apex 9166 de Mitutoyo con la que poder garantizar el máximo nivel de precisión en los componentes que fabrica.