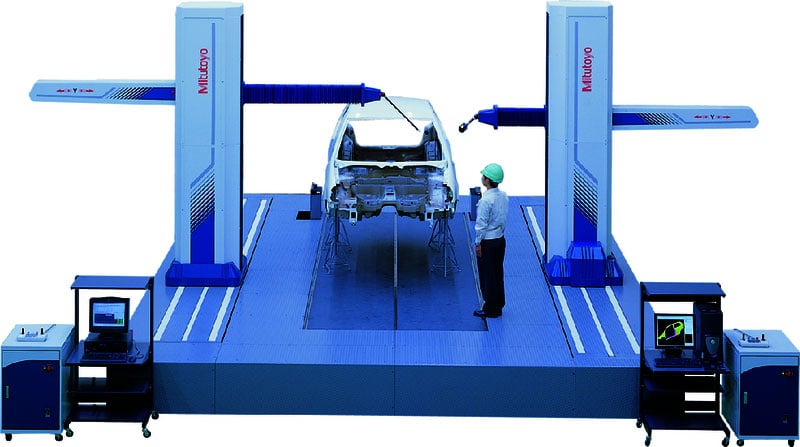

Large size 3D measurement

The Falcio-Apex and CARB series are large size and high-precision measuring machines designed for large and heavy components' measurement.

They guarantee a maximum permissible error from

MPEE = (3.5 + 4 L/1000) µm [Falcio-Apex series (Gantry type)]

MPEE = (15 + 20 L/1000) µm [CARB series (horizontal arm type)]

Speed and accuracy for your quality assurance

Ideal automatic 3D measurement solution: LARGE SIZE CMM

Mitutoyo has a very complete series of measuring machines for measuring large and heavy components.

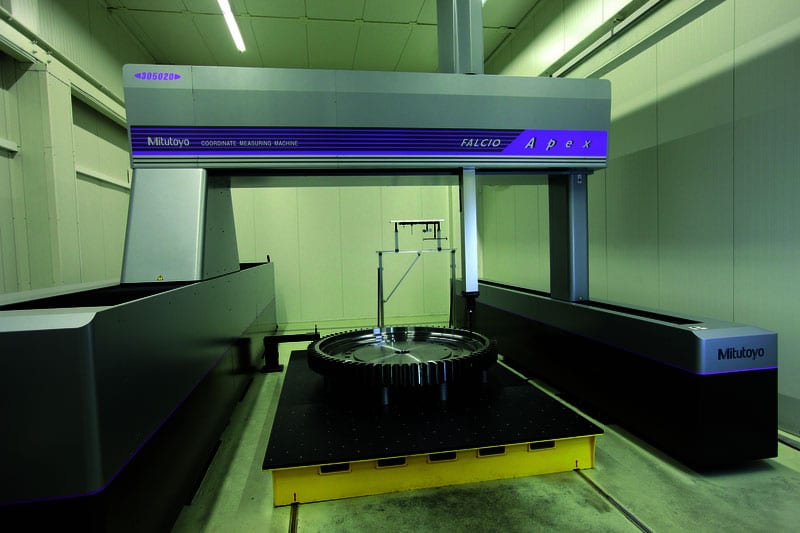

FALCIO-APEX G SERIES

High precision gantry type CNC CMM, designed to provide superior performance for your larger workpieces. It can work with contact probe, scanning probe, optical probe and 3D laser scanner. Used for measurements of large molds, parts of wind turbines, airplanes, ships, etc. Being anchored to the foundation of the pavement, this CMM allows an almost unlimited load mass since the work piece is not placed in the structure of the machine. They are compatible with multi-sensor applications.

- It has temperature compensation technology (sensors for the machine and part)

- Temperature compensation from 18°C to 22°C

- High accuracy

- High speed and acceleration

- High precision glass scale with resolution 0.1 µm

- Multi-Function Joystick Box including two levers and a speed adjustment

- Available in many different sizes from 2000 x 3000 x 1600mm to 3000 x 5000 x 2000mm.

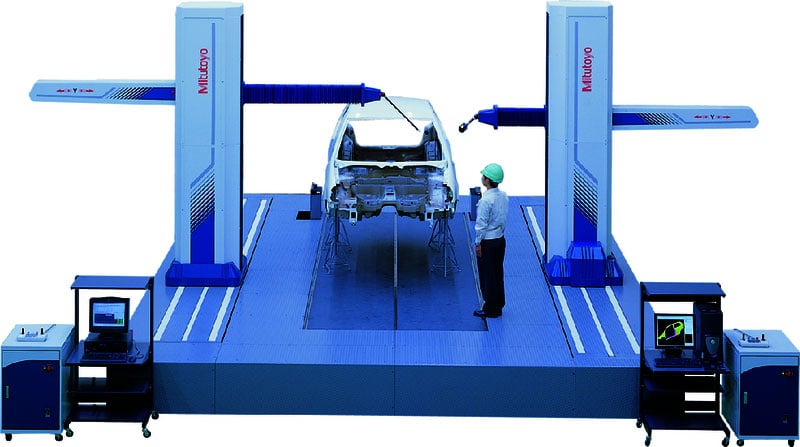

CARB SERIES

The CARB series is divided into 2 accuracy classes: CARB apex and CARB strato. Both models are available in single or dual arm type.

The CARB series has been designed to fit the requirements of your company: These machines can be installed at ground level or they can be integrated into the pavement for an easier transfer of parts.

They are compatible with multi-sensor applications.

- It has temperature compensation technology (sensors for the machine and part)

- Temperature compensation from 16°C to 26°C

- High accuracy

- High speed and acceleration

- Available in many different sizes from 4000 x 1400 x 1800 mm to 8000 x 1600 x 3000 mm.

- Touch-trigger probes

- Scanning probes

- Laser scanners like Mitutoyo’s SurfaceMeasure

- Vision probe QVP

- Surface Roughness SURFTEST Probe

Related Products and Services

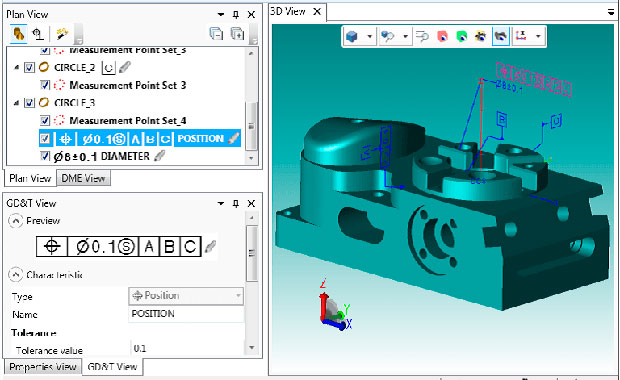

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

Mitutoyo's large size CMMs has been designed for high precision inspection of big parts from the automotive, aeronautical, energy, capital equipment ... etc sectors. The equipment is suitable for inspection of big machined parts, large stamping, turbine blades, large gears, big molds and dies ... etc.

From 4000mm to 8.000mm.

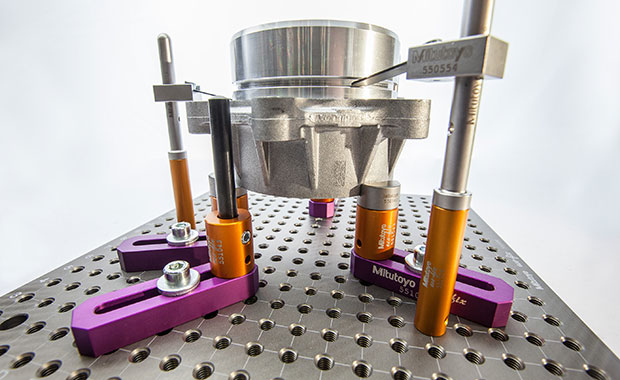

Measuring probes

You will have a versatile and flexible system, which you can incorporate the following probes.

Tactile scanning probes such as SP25M or SP80 for fast measurement with high point density

High precision, touch-trigger probes with a tip size down to 0.3 mm for probing the smallest features

Vision systems for fast 2D measurement

Laser scanning probes for inspection and reverse engineering tasks

Surface roughness SURFTEST probe

Automatic changing racks to maximize machine efficiency

Custom solution

Our engineering department can customize and integrate the coordinate measuring machine according to your requirements. Tell us what your challenge is and Sariki will advise you to identify which is the best solution for your specific case.

LOADING SYSTEM

You can incorporate manual, semi-automatic and automatic loading systems into the equipment

CABIN SYSTEM

We identify the cabin system that best suits your application

INTERACTION WITH PRODUCTION MANAGEMENT SYSTEMS

We guarantee 100% traceability of the process by integrating the CMM data with your MES/ERP system

CUSTOM PROGRAMMING

We have experienced staff in programming and measurement for the realization and implementation of measurement part-programs

TURNKEY PROJECT

If you are looking for a turnkey project you can trust on us. We work with you from the conception of the idea and definition of project conditions, prior acceptance, installation in your company, user training and technical assistance and support throughout the life of the project.

We face integration projects from a holistic view of inspection guidelines and are committed to comply hybridization technologies. We can develop an inspection solution that combines different technologies: three-dimensional machine, roughness, vision, etc.

Technical specifications

Measuring range

X = from 2000 to 4500 mm

Y = from 3000 to 6000 mm

Z = from 1200 to 2000 mm

Accuracy

(3.5 + 4L / 1000)µm

Repeatability

3,5µm

Driving speed

Up to 500mm/s

Driving acceleration

Up to 780 mm/s2

Temperature range

Up to 18ºC - 22ºC

Workpiece weight

Depending on the resistance of the pavement