Medición 3D ultra precisión

Las máquinas LEGEX te ofrecen figuras deprecisión líderes en el mundo para realizar los trabajos más exigentes.

Garantiza un error máximo admisible de MPEE =(0,28 + L / 1000) µm

Permite el aseguramiento de la calidad de tus piezas de forma precisa, flexible y a alta velocidad

Solución ideal de medición 3D CNC: LEGEX

Los productos manufacturados están mejorando continuamente en términos de mayor vida útil y menor consumo de energía, lo que a menudo se logra mediante la aplicación de tolerancias más estrictas.

Te permite verificar la dimensión de tus piezas de forma ultra precisa.

- Su estructura está fabricada de hierro fundido dúctil especial de grafito esferoidal que proporciona características de alta rigidez y atenuación de vibración.

- Los ejes X e Y trabajan de forma totalmente independiente. El movimiento del eje X no cambia la carga en el eje Y, por lo que no causa deformación.

- Controla la vibración mediante amortiguadores de aire aislantes con función de nivelación automática, que elimina virtualmente las vibraciones del suelo sin afectar a la estructura de la máquina.

- Realiza una compensación de temperatura efectiva de 18ºC a 22ºC. Además, los sensores de temperatura en cada eje y de la propia pieza de trabajo detectan cambios de temperatura en tiempo real y se utilizan para compensar la medida a 20ºC.

- LEGEX está equipada con reglas de vidrio cristalizado con una resolución de 0,01 μm.

Te permite verificar la dimensión de tus piezas a alta velocidad. LEGEX está equipada con una nueva unidad de control, la UC-400. La UC-400 permite mediciones de alta velocidad y movimientos con precisiones impresionantes.

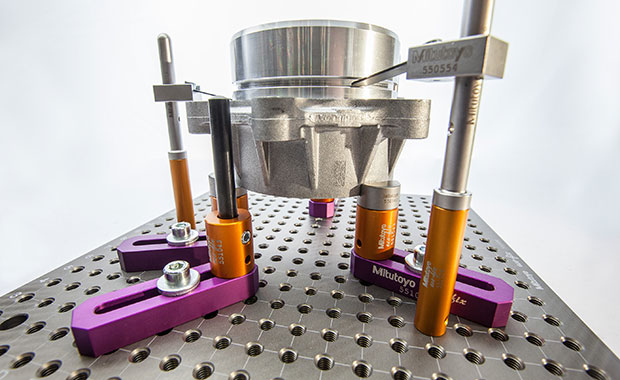

Te ofrece flexibilidad. Se puede equipar con casi cualquier tipo de palpador, como:

- Sondas de contacto

- Sondas de escaneado

- Escáneres láser como el SurfaceMeasure Mitutoyo

- Palpador de visión QVP Mitutoyo

- Palpador de rugosidad superficial SURFTEST Mitutoyo

Todas las configuraciones de palpador se pueden cambiar automáticamente dentro de un ciclo de medición. Hay muchos tipos diferentes de cambiadores de módulos de palpador disponibles para cumplir con los requisitos de su aplicación.

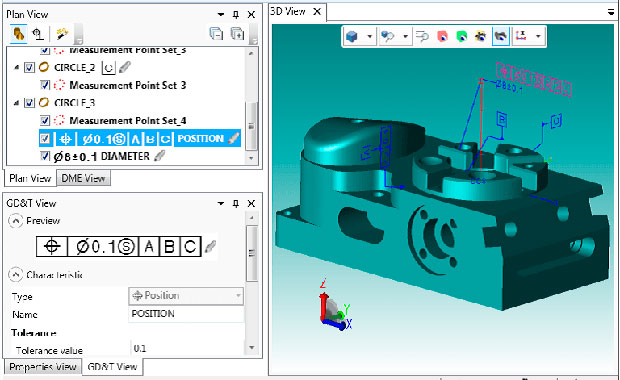

Productos y servicios relacionados

Junto a este equipo se pueden utilizar diferentes accesorios y software en función de las necesidades y usos que se le vayan a dar. Sariki le asesorará en todo momento sobre el complemento más adecuado a su caso, si así lo desea puede cosultarnos sin compromiso.

Aplicaciones

LEGEX ha sido diseñada para la inspección de ultra precisión de piezas del sector automoción, aeronáutico, salud, bienes de equipo, máquina herramienta, consumo…etc. El equipo es adecuado para la inspección de pieza mecanizada, estampación, inyección de plástico/aluminio, álabes de turbina, engranajes, moldes y matrices…etc.

Desde 500 mm hasta 1.200mm

Sondas de medición

Tendrás un sistema versátil y flexible, al que podrás incorporar casi cualquier tipo de sonda.

Sondas de escaneado táctiles como SP25M o SP80 para una medición rápida con alta densidad de puntos.

Sondas táctiles de alta precisión con un tamaño de punta de hasta 0,3 mm para medir las características más pequeñas.

Sistema de visión para la medición rápida 2D.

Sistema de escáner láser para tareas de inspección e ingeniería inversa.

Sistema de rugosidad superficial SURFTEST.

Auto-cambiadores de módulos para maximizar la eficiencia de la máquina.

Solución personalizada SK/solutions

Nuestro departamento de ingeniería puede personalizar y adecuar la máquina de medición por coordenadas LEGEX a tus requerimientos. Cuéntanos cuál es tu reto y desde Sariki te asesoraremos para identificar cual es la mejor solución para tu caso concreto.

SISTEMA DE CARGA

Puedes incorporar al equipo sistemas de carga manuales, semi-automáticos y automáticos.

SISTEMA DE CABINA

Identificamos el sistema de cabina que mejor se adapte a tu aplicación.

INTERACCIÓN CON LOS SISTEMAS DE GESTIÓN DE LA PRODUCCIÓN

Puedes tener trazabilidad 100% del proceso integrando los datos de la MMC con tu sistema MES.

PROGRAMACIÓN PERSONALIZADA

Podemos ocuparnos de preparar los programas de medición de tus piezas.

PROYECTO LLAVE EN MANO

Si lo que buscas es un proyecto llave en mano puedes contar con nosotros. Colaboramos contigo desde la concepción de la idea y definición de condiciones del proyecto, aceptación previa, instalación en tu empresa, formación de usuarios y asistencia técnica y soporte durante toda la vida del proyecto.

Especificaciones técnicas

Rango de Medición

X = de 500mm hasta 1.200mm

Y = de 700mm hasta 1.200mm

Z = de 450mm hasta 1.000mm

Precisión

(0,28 + L / 1000) µm

Repetibilidad

0,28 μm

Velocidad máxima de accionamiento

Hasta 200mm/s

Aceleración máxima

Hasta 980 mm/s2

Rango de temperatura permitido

Hasta 18ºC a 22ºC

Peso máximo de la pieza

De 180 a 1.000 kg.