Multisensor probes

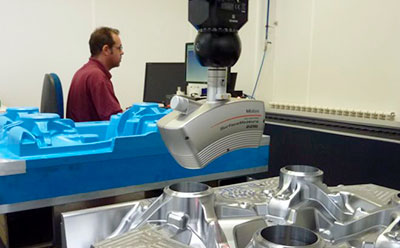

Te proponemos combinar diferentes tecnologías en un único sistema de medida con el objetivo de optimizar tu proceso de inspección. Es válido para aplicaciones muy diversas del sector automoción, aeronáutico, salud, bienes de equipo, máquina herramienta, consumo…etc.

Interesante para aquellas empresas que necesitan tener una validación completa de la pieza que fabrican, tienen que verificar muchas características geométricas y superficiales, y quieren optimizar proceso.

Mide con diferentes tecnologías en un único sistema

Poder incorporar diferentes tecnologías dentro de una máquina tridimensional te ofrece muchas ventajas.

Una de las más importantes es la flexibilidad. Nuestras máquinas tridimensionales pueden equiparse con una gran variedad de sondas:

- Sondas de contacto

- Sondas de medición en continuo

- Escáneres láser

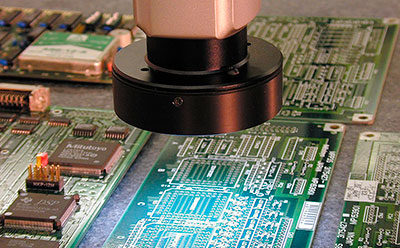

- Sonda de visión

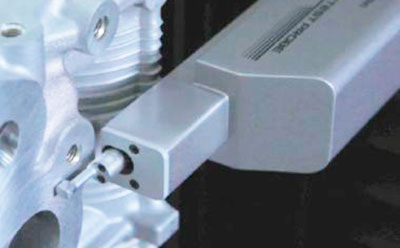

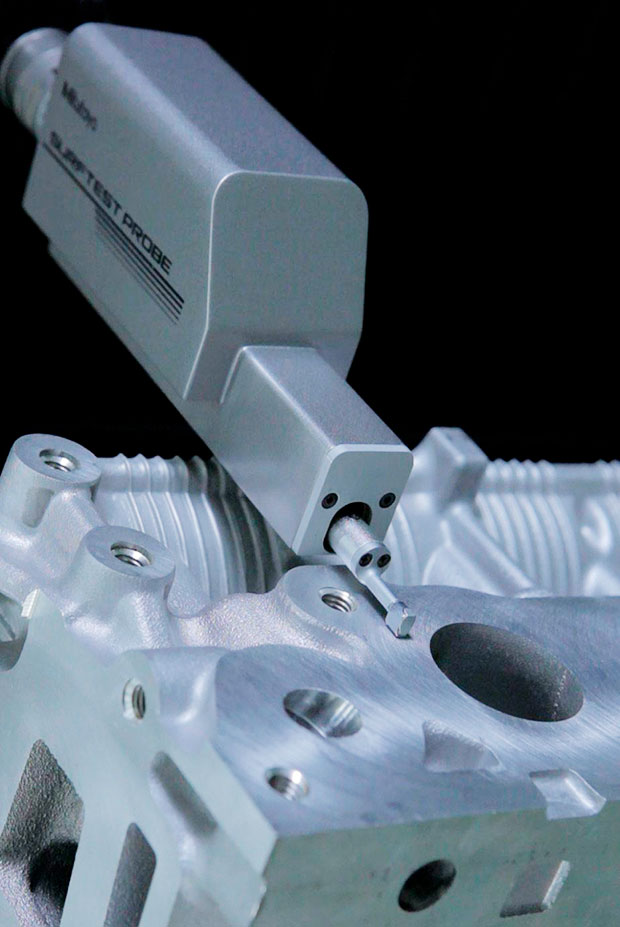

- Sonda de rugosidad superficial

Diferentes tecnologías dentro de una máquina tridimensional

Todas las configuraciones de sonda se pueden cambiar automáticamente dentro de un ciclo de medición y todos los datos se gestionan desde una única plataforma, facilitando así la recopilación de resultados durante el proceso de inspección.

Hay muchos tipos diferentes de cambiadores de módulos de palpador disponibles para cumplir con los requisitos de su aplicación.

Además, las soluciones de software integradas brindan opciones para la evaluación estadística de datos medidos, mediciones de perfil con respecto a datos CAD, así como la digitalización de superficies de forma libre.

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología.

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras sondas para incorporar a las máquinas de medir por coordenadas

Aumenta tu productividad y digitaliza tus procesos utilizando un único sistema. Genera una copia digital de tu pieza

La tecnología de medición de acabado superficial ya se puede utilizar directamente en la máquina tridimensional

QVP es un cabezal de medición óptico diseñado específicamente para máquinas de medición por coordenadas

La tecnología REVO© y PH20 añaden 2 ejes adicionales a los 3 que ya dispone la máquina de medición por coordenadas

StyliCleaner es una solución automática para eliminar el polvo o las virutas de los palpadores de las máquinas de medición Mitutoyo

Webinar

Caso de éxito

UMBOR ha adquirido una máquina de medición 3D Mitutoyo Crysta Apex S 12.20.10 equipada con la solución de escáner láser SurfaceMeasure y probeta de escaneado en continuo SP-25 para escanear rápida y eficazmente el 100% del volumen de sus moldes.