Medición 3D con escáner láser

La sonda SurfaceMeasure genera una copia digital de tu pieza a alta velocidad.

Aumenta tu productividad y digitaliza tus procesos utilizando un único sistema.

Solución ideal de medición 3D con escáner láser: SURFACE MEASURE

Cada vez más, el control de calidad industrial requiere aplicabilidad universal, versatilidad y automatización a partir de tecnologías de medición. Demandas que se cumplen con éxito principalmente mediante máquinas de medición por coordenadas (MMC) con su enorme gama de capacidades.

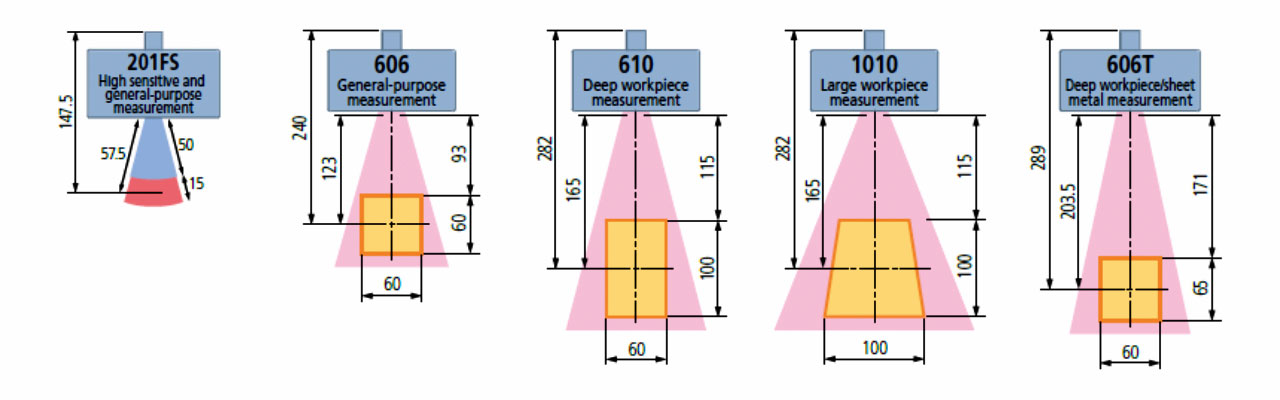

La tecnología de escáner láser se puede instalar en máquinas tridimensionales nuevas o existentes, de las series CRYSTA, STRATO y FALCIO, aumentando así la productividad del proceso de medición mediante la adquisición de más información en menos tiempo. Con un elevado número de aplicaciones, permite la adquisición rápida de la información completa de la superficie de la pieza (nube de puntos), para posteriormente compararla contra el CAD y realizar ingeniería inversa.

Compatible con PH10M/MQ y auto cambiadores automáticos.

La intensidad del láser se ajusta de forma automática, así como la sensibilidad de la cámara según las características de la pieza.

Escanea a alta velocidad. Ratio de adquisición hasta 75.000 puntos por segundo.

Mediciones sin spray incluso para superficies brillantes o múltiples colores.

MSURF es el software de Mitutoyo que utiliza los datos de la nube de puntos de alta densidad obtenidos de la superficie de la pieza para analizarlos de diferentes formas: verificando las características geométricas, evaluando superficies de formas libres y formas de perfil, y verificando tolerancias en comparación con los datos CAD.

Aplicaciones

Puedes medir prácticamente cualquier material, incluyendo el mecanizado, semiacabado, estampado, forjado, fundido, metales pintados, machos de arena, fibra de carbono, plásticos, arcilla, goma, madera y cerámica.

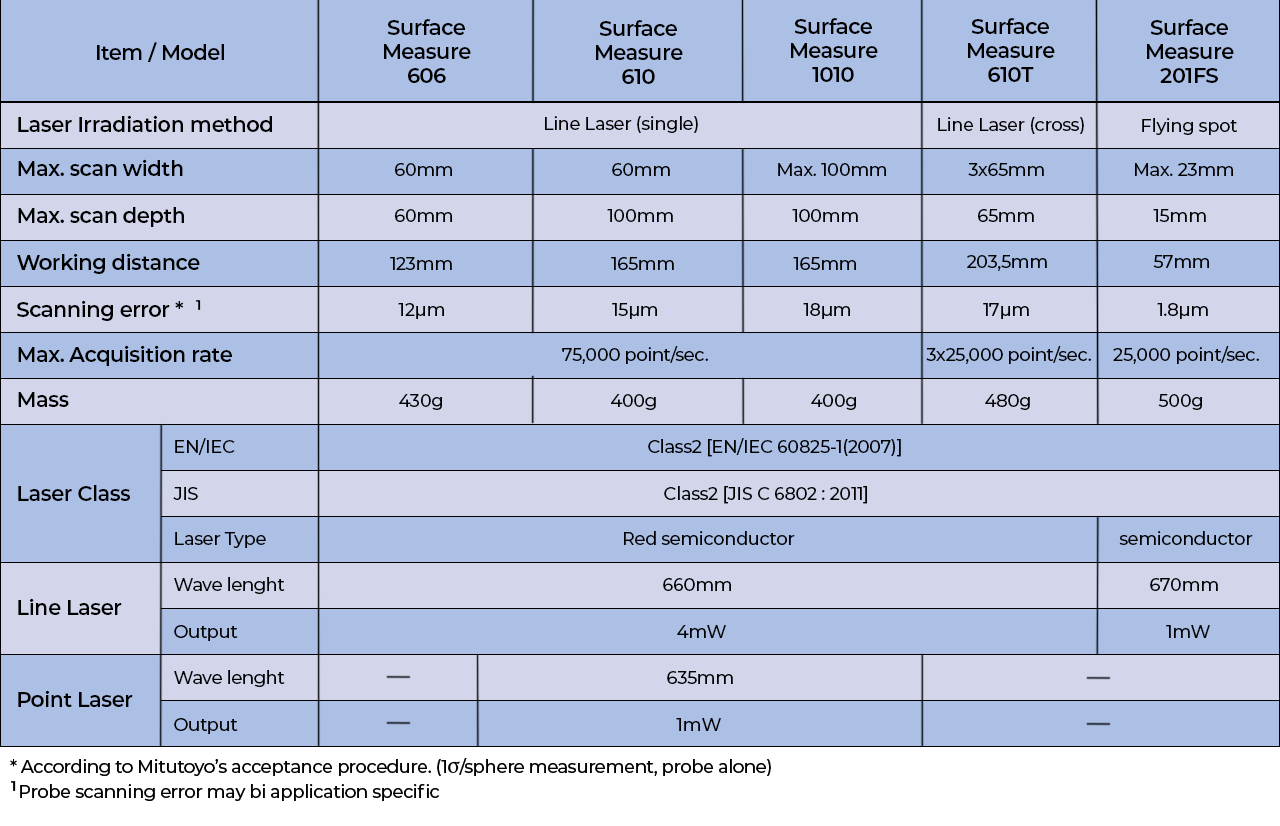

Especificaciones técnicas