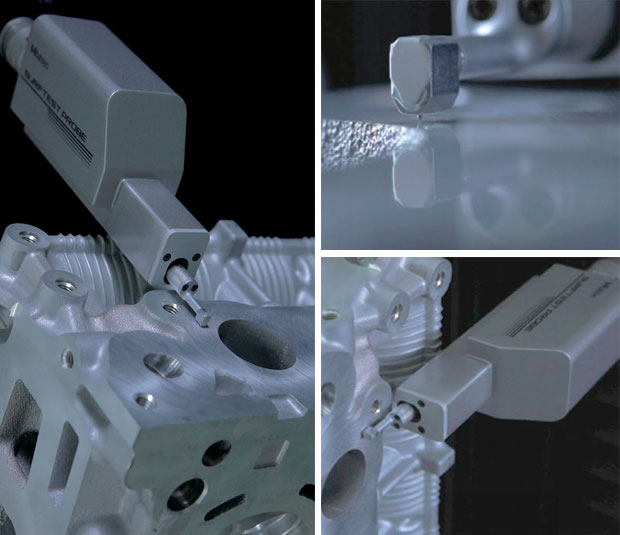

Medición 3D con sonda de rugosidad

La tecnología de medición de acabado superficial ya se puede utilizar directamente en la MMC. En lugar de tener que llevar la pieza de trabajo a otro aparato de medición o utilizar sistemas portátiles adicionales, la sonda SURFTEST añade la capacidad de medición de la rugosidad a tu máquina tridimensional y, de esta manera, evita todo el coste e inconveniencia de los sistemas adicionales.

Solución ideal de medición 3D con rugosímetro integrado: SURFTEST PROBE

SURFTEST se basa en la tecnología demostrada de la serie SJ-310 e incorpora toda su gama de detectores altamente cualificados desarrollados para manejar aplicaciones especializadas tales como la medición de rugosidad en engranajes, en el interior de orificios pequeños o ranuras profundas, además de las tareas de medición sencilla de superficies planas.

Beneficios

Disponibles cinco tipos de detector para diferentes aplicaciones

Alta precisión. La MMC no se mueve durante la medición

Produce todos los resultados durante el ciclo de medición de la MMC

Salida gráfica y numérica

Emite un informe de medición para todos los requisitos de GD&T (Dimensionamiento y Tolerancias Geométricas)

Beneficios

Disponibles cinco tipos de detector para diferentes aplicaciones

Alta precisión. La MMC no se mueve durante la medición

Produce todos los resultados durante el ciclo de medición de la MMC

Salida gráfica y numérica

Emite un informe de medición para todos los requisitos de GD&T (Dimensionamiento y Tolerancias Geométricas)

Aplicaciones

La sonda SURFTEST puede medir rugosidad y ondulación de gran variedad de piezas mecanizadas y fundidas, rodamientos, ejes, sellos, Cojinetes, Rodillos…etc.

Especificaciones técnicas

Longitud a accionar

17.5 mm (la distancia de recorrido libre delante y detrás de la medición también está incluida)

Método de accionamiento (*)

Un movimiento alternativo

Velocidad de trazado (**)

Medición: 0.25 mm/s

0.5 mm/s

0.75 mm/s

Referencia

06AEN891

Peso

350 gr

Gama / Resolución

Automático / Dependiendo de una gama de medición

360µm / 0.006 µm

100µm / 0.002 µm

25µm / 0.0004 µm