Tomografía industrial

Te proponemos una solución de medición que te permitirá identificar defectos y verificar la geometría de tus piezas de forma interna y externa mediante tecnología de rayos X. Adecuado cuando no puedes realizar ensayos destructivos y necesitas verificar tus piezas con alta precisión.

Aplicaciones típicas: análisis de defectos, análisis de distribución de material, inspección dimensional, análisis de espesores, comparación contra CAD, ingeniería inversa…etc.

Muchas posibilidades para el control de calidad

Muchas empresas del sector automoción, aeronáutico, médico, etc., se encuentran con la problemática de no poder saber cómo están internamente sus piezas con estructuras complejas, siendo estas necesarias para el buen funcionamiento de un componente. Hasta ahora, la única fórmula disponible era realizar ensayos destructivos, generando más costes y mucho tiempo. Pero los rayos X comúnmente utilizados en el sector salud han comenzado a aplicarse a nivel industrial ofreciendo muchas posibilidades para el control de calidad.

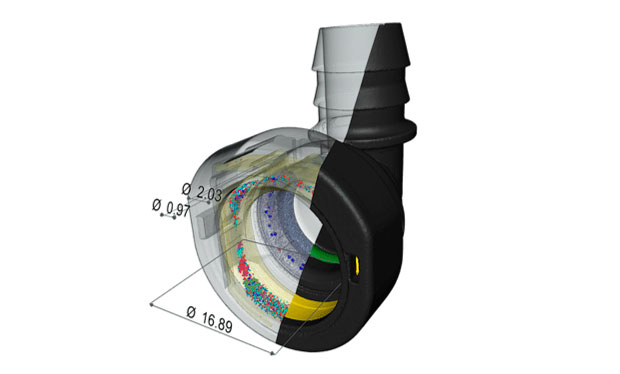

La tomografía computerizada (CT) básicamente es un proceso no destructivo en el que se capturan imágenes (radiografías) desde todas las direcciones mediante radiación penetrante y posteriormente permite la reconstrucción de un volumen 3D del componente, basándose en los valores de intensidad de las imágenes proyectadas. Mediante un avanzado software de análisis se puede detectar la presencia de poros o defectos interiores, así como la medición de características dimensionales internas inaccesibles.

Proceso no destructivo de captura de imágenes

Asimismo, es posible analizar el comportamiento y ajuste de conjuntos ensamblados, realizar análisis de rotura de componentes, inspección de componentes complejos de plástico inyectado, análisis y test de materiales. El sistema puede exportar el modelo obtenido a un formato STL o incluso compararlo con el modelo CAD nominal.

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras soluciones de tomografía industrial

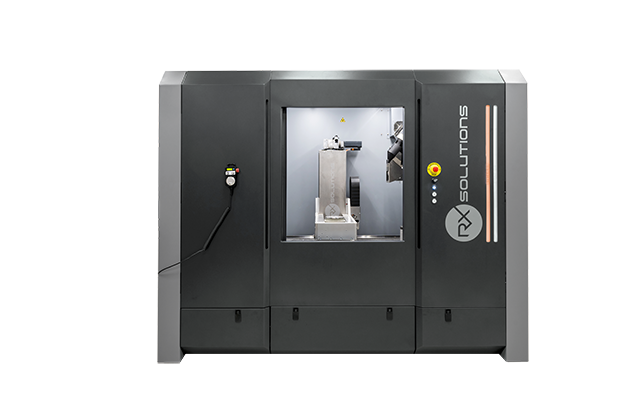

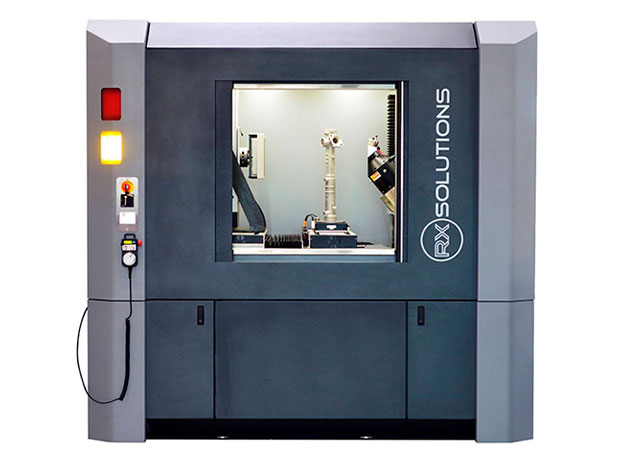

Easy Tom S, es un sistema CT de rayos X altamente flexible con un volumen de inspección de hasta 230mm x 380mm

Easy Tom L, es un sistema CT de rayos X altamente flexible con un volumen de inspección de hasta 450mm x 640mm

Easy Tom XL, es un sistema CT de rayos X altamente flexible con un volumen de inspección hasta 600mm x 720mm.