Inspección flexible en proceso

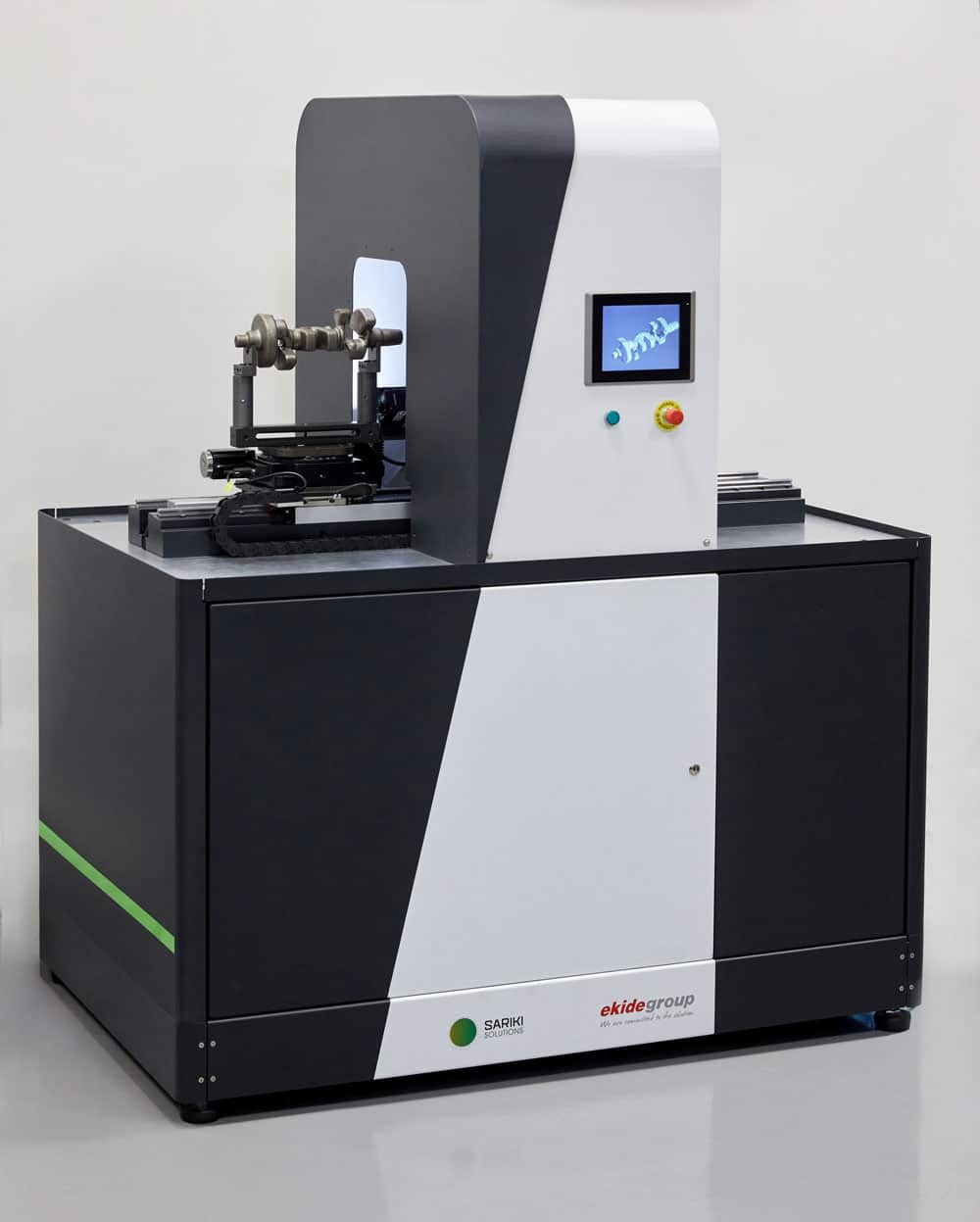

Ekide Group, desarrollador de soluciones tecnológicas basadas en visión artificial y Metrología Sariki, nos hemos aliado para ofrecer al mercado soluciones flexibles para la inspección de precisión en proceso y a alta velocidad.

El centro tecnológico Vicomtech, experto en tecnologías de visualización colabora en la alianza aportando su know-how en tecnologías de visión y algoritmos de procesamiento de información.

Inspección a alta velocidad en producción

Valor añadido de la solución

Todas las soluciones están diseñadas para asegurar la calidad de la inspección trabajando de forma continuada dentro de entornos productivos de alta exigencia.

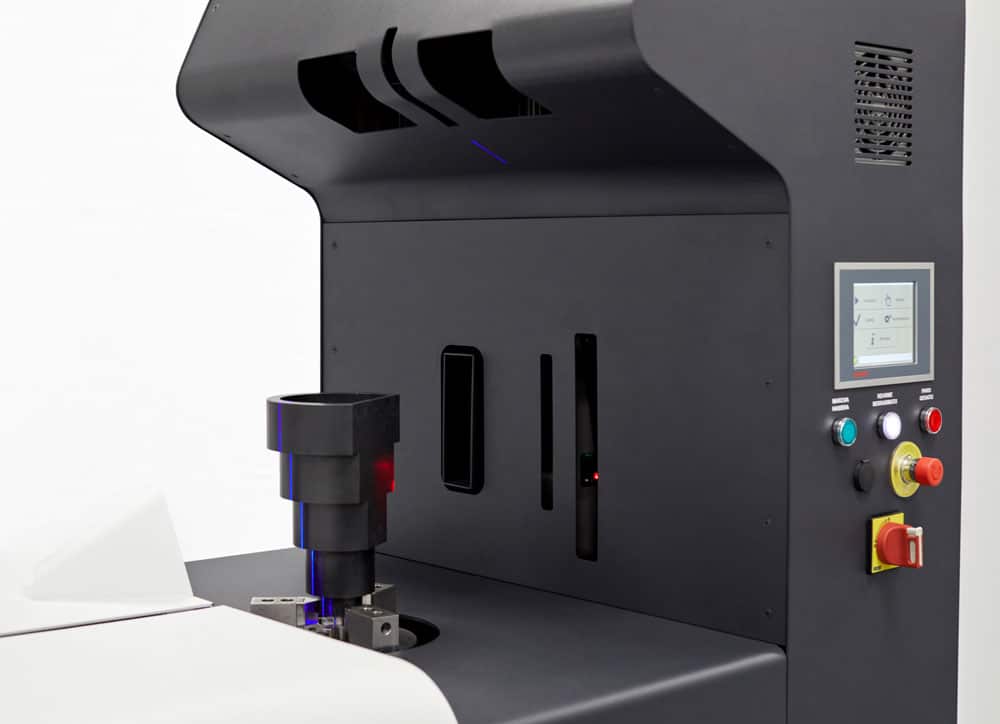

- Seleccionamos los escáneres de alta frecuencia en función de la precisión demandada por la aplicación.

- La solución dispone de un sistema automático de ajuste que permite adaptar el número y disposición de los escáneres en función de la geometría y dimensiones de las piezas a inspeccionar.

- Podemos cubrir todas las necesidades del sector industrial. Ofrecemos la posibilidad de desarrollar e incorporar nuevas funcionalidades a la aplicación para satisfacer necesidades de aplicación específicas.

2 modelos

Actualmente ofrecemos 2 modelos (lineal y rotativo) que a su vez son completamente flexibles.

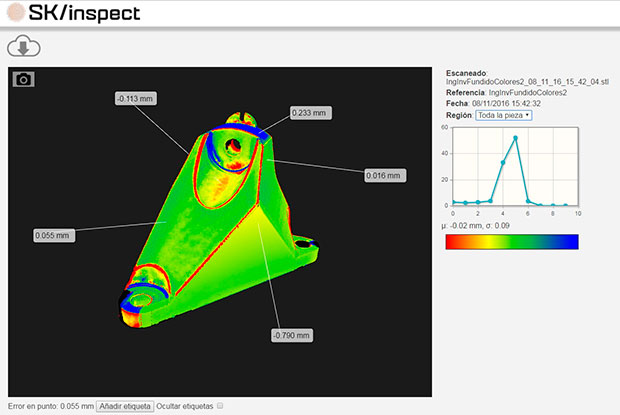

Software SK/inspect

SK/inspect es el software con el que se realizan las mediciones y analizan los resultados. Es un software basado en nube de puntos y diseñado para la evaluación dimensional y geométrica completa de la pieza.

Dispone de una interfaz gráfica diseñada para facilitar la interacción con el operario y el análisis de los datos medidos directamente en proceso. Además, los datos de las mediciones se exportan a la plataforma web para su análisis desde puestos externos a la célula de inspección.

- Reconstrucción de modelo 3D

- Alineamiento de piezas

- Cálculo de elementos y secciones

- Tolerancias dimensionales y geométricas

- Color mapping y etiquetas de desviación

- Informes y bases de datos

Productos y servicios relacionados

Junto a este equipo se pueden utilizar diferentes softwares en función de las necesidades y usos que le vayas a dar. Te asesoraremos en todo momento sobre el complemento más adecuado en tu caso si así lo deseas. Puedes consultarnos sin compromiso.

Aplicaciones

Cadena de suministro de piezas del sector de automoción, sobre todo para piezas con geometrías complejas, donde se requiere una producción a una cadencia alta y sea imprescindible la inspección de calidad de piezas para garantizar el proceso de fabricación.

Cadena de suministro de piezas del sector aeronáutico, donde la alta cadencia de producción no es necesaria, pero las exigencias de calidad de las piezas implican la necesidad de inspeccionar el 100% de la producción.

Solución personalizada SK/solutions

Ahorro de tiempos de inspección

Podrás inspeccionar el 100% de las piezas fabricadas a alta cadencia, ajustándolas al ciclo de la línea de producción. Ahorrarás tiempo y costes de calidad

Optimizado para medición en taller

Podrás trasladar el control de calidad a alta velocidad al espacio de producción sin la necesidad de capacitación avanzada para todos los usuarios, simplificando el proceso de medición, lo que resulta en una mejora significativa de tu productividad

Solución flexible

Te ofrecemos una solución integral flexible que se adapta a todas tus necesidades

Solución personalizada

Nuestro departamento de ingeniería puede personalizar y adecuar la solución de inspección a tus requerimientos. Cuéntanos cuál es tu reto y desde Sariki te asesoraremos para identificar cual es la mejor solución para tu caso concreto