Medición 3D en proceso

Te proponemos tecnologías de medición 3d especialmente diseñadas para realizar mediciones por contacto directamente en entorno de producción.

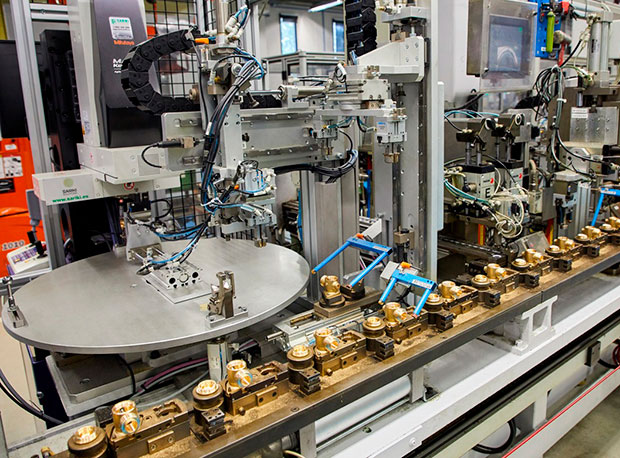

Medición de pieza mecanizada (culatas, carcasas de motor, bloque motor, porta manguetas y brazos, tulipas, discos y tambores de freno, amortiguadores…etc.), así como medición de piezas durante el proceso de producción, en fases intermedias previas al mecanizado final (operaciones de desbaste).

Sariki es distribuidor oficial de MITUTOYO para España

Tecnología para medir en proceso productivo

En todo proceso de fabricación la inspección dimensional asegura que los resultados cumplan las especificaciones de tolerancia requeridas para su cometido. Estos controles se deben realizar de forma periódica con el fin de asegurar que ninguna variable del proceso de producción se encuentre fuera de sus condiciones normales de trabajo.

La industria 4.0 impone la necesidad de optimizar los procesos para conseguir la máxima productividad, a la vez que se elevan los estándares de calidad.

En este nuevo escenario, Sariki ha avanzado más allá de la captura de datos aislados de la metrología tradicional, y ha trasladado la metrología dimensional, habitualmente asociada al control de calidad en laboratorio, a la planta de fabricación integrándola en las líneas de producción como una fase más del proceso.

Beneficios

Obtener datos útiles para mejorar la calidad de la geometría de tus piezas

Controlar y optimizar tu proceso

Tomar decisiones a la velocidad que la producción demanda

Aumentar los estándares de calidad

Solucionar problemas en tiempo real, teniendo un verdadero conocimiento de donde está el origen

Aumentar la velocidad de inspección para impactar el mínimo tiempo en la línea de producción

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología.

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras soluciones de medición 3D en proceso

Mitutoyo Mach V está diseñada para la medición rápida y precisa en proceso productivo

MACH 3A es una máquina tridimensional de eje horizontal especialmente diseñada para la medición en proceso productivo

MACH KoGaMe es la solución ideal para células automatizadas en entornos de taller

Mitutoyo Mistar es la nueva solución de medición compacta para entornos de producción

Caso de éxito

GKN Driveline Legazpi ha apostado por Sariki para afrontar un proyecto muy ambicioso de inspección en producción, donde el entorno sin duda ha sido uno de los elementos que lo han convertido en un verdadero reto tecnológico.