Digitalizado 3D en línea

Te proponemos una solución para el digitalizado 3D en línea, realizando control de calidad sin contacto rápido y eficiente para tu proceso productivo, mediante la tecnología de luz estructurada.

Una solución orientada a satisfacer las exigencias del sector automoción principalmente, pero también con aplicación en el sector aeronáutico.

Solución desarrollada por Sariki

Tecnología de digitalizado 3D en línea

La medición y verificación es un aspecto clave que garantiza el salto cualitativo a niveles de productividad y competitividad, es por ello por lo que la integración de la metrología en la línea de producción es cada vez más necesaria sobre todo en los sectores tan exigentes como automoción y aeronáutica.

Para los fabricantes es imprescindible tener información precisa para la toma de decisiones, y los requerimientos de medir cada vez más unidades están impulsando la verificación del 100% de la producción.

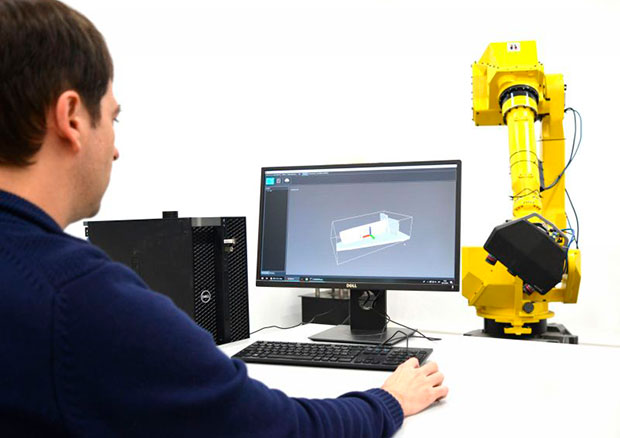

Para cubrir estas necesidades, los tiempos de ciclo tienen que disminuir notablemente, y la solución es el digitalizado completo de la pieza dentro de la línea de producción mediante la luz estructurada. Midiendo en cualquier posición, capturando nubes de puntos tanto para la inspección dimensional como para ingeniería inversa.

Los controles de calidad sin contacto capturan información de calidad detallada fácilmente interpretable con tiempos de medición más cortos. De esta manera, podrás trasladar el control dimensional al área de producción, sin la necesidad de capacitación avanzada para todos los usuarios de planta.

Beneficios

Obtener en tiempo real el control y feedback

Disminuir el número de repeticiones

Rediseñar en base a datos puros y dimensiones trazables

Tomar decisiones a la velocidad que la producción demanda

Reducir costes y vencimientos ajustados

Reducir la chatarra en caso de corrección de errores

Mejorar la productividad al trasladar el control de calidad a planta

Obtener un conjunto de datos del 100% de la pieza, con más cantidad de información

Comparar las mediciones directamente con las referencias, al igual que obtener las variaciones gráficas

Proyecto integral adecuado a tus necesidades

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuales son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 35 años de experiencia en el sector de la metrología.

Te acompañamos a lo largo de toda la vida del proyecto

Conoce nuestras soluciones de digitalizado 3D en línea

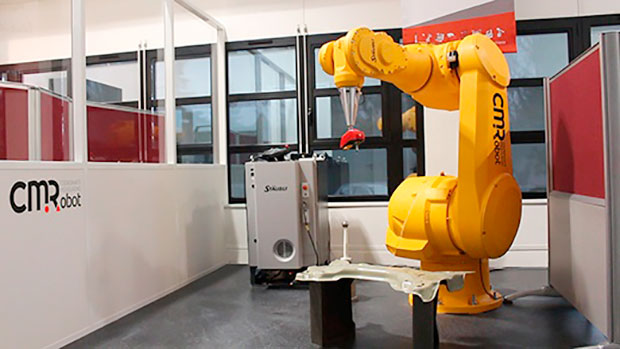

Solución robotizada de luz estructurada para inspección en proceso

Solución robotizada de escáner láser para inspección en proceso