CMRobot

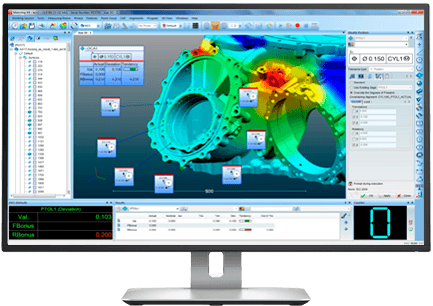

Digitalizado 3D en proceso

CMRobot es una solución de hardware y software de inspección avanzada en proceso. Está basado en la integración de un escáner 3D en un robot flexible de ejes múltiples.

Este sistema de medición 3D sin contacto, utiliza la tecnología de escáner láser 3D sin necesidad de utilizar targets o sistemas de seguimiento. Se puede incorporar una sonda de contacto al escáner láser.

Esta solución robotizada de medición óptica te dará un control de calidad eficiente en tu proceso de fabricación, realizando mediciones rápidas y precisas de forma completamente automatizada directamente en la planta productiva. Además, los datos generados pueden integrarse fácilmente en el flujo de trabajo.

CMRobot combina:

- Robot del fabricante Stäubli

- Escáner Kreon Zephyr II Blue con sensor óptico y táctil

- Software metrolog X4 i-robot

La solución CMR está disponible para su uso con la gama TX de robots Stäubli (TX 60, TX 90 y TX 200). Usando un Staubli TX 200 con sonda de contacto, puedes lograr una precisión de +/- 100 μm. Al escanear con el escáner Zephyr II Blue, la precisión es +/- 150 μm (estos datos son efectivos para un volumen de medición de un metro cúbico).

Esta solución ha sido desarrollada en colaboración entre Staübli, Kreon y Metrologic.

Productos y servicios relacionados

Junto a este equipo se pueden utilizar diferentes softwares en función de las necesidades y usos que le vayas a dar. Te asesoraremos en todo momento sobre el complemento más adecuado en tu caso si así lo deseas. Puedes consultarnos sin compromiso.

Aplicaciones

CMRobot ha sido diseñado para la inspección en la línea de piezas del sector automoción y aeronáutico.

El equipo es adecuado para medir, procesar y obtener la mayor información posible de una forma más rápida, sobre todo para procesos automatizados con alta cadencia de piezas. Está orientado a medición en línea, para integrarse en cualquier línea de producción ofreciendo una experiencia de medición 3D automatizada, desde la planificación y exploración, hasta el análisis y los informes.

Solución personalizada

Ahorro de tiempos de inspección

Con la solución CMRobot, optimizada para medición en taller, podrás ahorrar en tiempo y costes, ya que te aporta la información exacta y necesaria tanto para los diseños como para los controles da calidad de una forma mucho más rápida y precisa

Optimizado para medición en taller

Podrás trasladar el control de calidad a alta velocidad al espacio de producción sin la necesidad de capacitación avanzada para todos los usuarios, simplificando el proceso de medición, lo que resulta en una mejora significativa de tu productividad

Solución flexible

Te ofrecemos una solución integral flexible que se adapta a todas tus necesidades

Solución personalizada

Nuestro departamento de ingeniería puede personalizar y adecuar CMRobot a tus requerimientos. Cuéntanos cuál es tu reto y desde Sariki te asesoraremos para identificar cual es la mejor solución para tu caso concreto