ViciVision serie Techno

Alta resolución para medir piezas de revolución directamente en el taller.

Desde 40 hasta 180 mm de diámetro, desde 300 hasta 1250 mm de longitud, la gama modular de la serie Techno te permite elegir el modelo de máquina más adecuado para tu producción.

Diseñado para su uso en producción

- Cada pieza producida por el torno CNC o por el centro de rectificado puede ser sencillamente medida por los operarios en pocos segundos.

- Un equipo de medición sirviendo a múltiples tornos CNC. La misma máquina de medición puede ser utilizada por varios operarios a la vez para la inspección de piezas de diferentes máquinas de producción.

- Las máquinas que mejoran la productividad. Los operarios son más autónomos durante el proceso de inspección. Pueden ajustar el desplazamiento de máquina antes de que los valores estén fuera de la tolerancia, contribuyendo a reducir el porcentaje de rechazos.

- Con el lector de código de barras, el operario puede cambiar rápidamente de una referencia a otra sin riesgo de error y al mismo tiempo puede comprobar diferentes lotes.

- Gracias a la amplia gama, el usuario final puede elegir el campo de medición más adecuado.

- La capacidad de carga de las máquinas más grandes ha aumentado hasta 60 kg.

Mediciones disponibles

Mediciones estáticas:

- Diámetros

- Longitudes

- Ángulos

- Radios

- Distancias y ángulos entre puntos y líneas

- Diámetros medios

Mediciones geométricas:

- Simetrías

- Paralelismos

- Perpendicularidad

Mediciones de roscas:

- Diámetros nominales

- Diámetros internos

- Diámetros medios

- Ángulos de cresta

- Paso

- Diámetro de varilla

Mediciones de forma:

- Diámetros de rotación

- Roundness

- Coaxialidad

- Oscilación

- Cilindricidad

- Diferencia angular

Medidas de tuerca:

- Entrecaras

- Asimetría angular

- Posición angular

Comparación DXF (opcional):

- Distancias desde perfil

- Distancias desde tolerancia

- GD&T

Mediciones disponibles

Mediciones estáticas:

- Diámetros

- Longitudes

- Ángulos

- Radios

- Distancias y ángulos entre puntos y líneas

- Diámetros medios

Mediciones geométricas:

- Simetrías

- Paralelismos

- Perpendicularidad

Mediciones de roscas:

- Diámetros nominales

- Diámetros internos

- Diámetros medios

- Ángulos de cresta

- Paso

- Diámetro de varilla

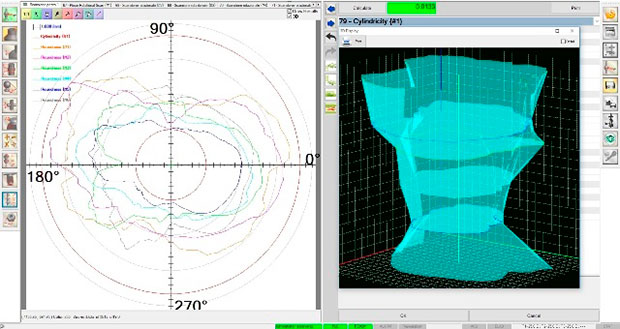

Mediciones de forma:

- Diámetros de rotación

- Redondez

- Coaxialidad

- Oscilación

- Cilindricidad

- Diferencia angular

Medidas de tuerca:

- Entrecaras

- Asimetría angular

- Posición angular

Comparación DXF (opcional):

- Distancias desde perfil

- Distancias desde tolerancia

- GD&T

Almacenamiento de datos

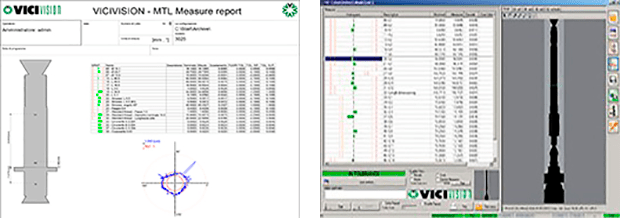

El sistema almacena todos los datos con propósitos estadísticos y de trazabilidad, genera informes de medición y monitoriza la tendencia de fabricación, satisfaciendo las necesidades de la industria 4.0.

Medición óptica + sonda de contacto

La combinación de funciones ópticas y táctiles lo convierten en un sistema de control completo para piezas de revolución.

La serie Techno ahora permite incluir una sonda de escaneado de 3 ejes de Renishaw, montada en la parte superior de la fuente de luz. La sonda es intercambiable y cubre toda el área de longitud.

Podrás medir:

- Desplazamiento axial y radial

- Longitud

- Planitud

- Perpendicularidad

- Ancho de chavetero

- Profundidad de chavetero

- Longitud de chavetero

Software completo

La nueva versión MTL 8.10 está diseñada para mejorar la fase de control y ampliar aún más el número de mediciones posibles. Incluye herramientas específicas para mediciones estáticas y dinámicas, y herramientas dedicadas para roscas de tuercas, árboles de levas, turbinas, etc.

Características avanzadas

Las nuevas funciones automáticas ayudan al operador en la auto-programación, carga automática del programa de la pieza, programación asistida paso a paso y comparación DXF.

Informes de medición

El software permite al usuario imprimir o exportar informes de medición en pdf completos y personalizados. Los resultados de las mediciones se pueden visualizar en histogramas para consulta inmediata.

Aplicaciones

Con la serie Techno puedes medir piezas de revolución como árboles de levas, válvulas, ejes de transmisión, tuercas, etc.…

Solución personalizada SK/solutions

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 34 años de experiencia en el sector de la metrología.

Especificaciones técnicas

Pieza máxima medible

de 300x40mm a 1250x180mm

Tamaño máximo de carga

de 315x120mm y 10Kg a 1300x240 y 60kg

Precisión en diámetros

de 1,5 + L[(mm)/200)] μm a 2+L[(mm)/100)] μm

Precisión en longitud

de 4 + L[(mm)/200)] μm a 5+L[(mm)/100)] μm

Repetibilidad en diámetros

de 0,3 μm a 0,4 μm

Repetibilidad en longitud

1,2 μm a 3 μm