Roundness

The verification of errors of form requires a perfect combination of the precision of the measurement system with an optimal positioning of the piece to measure. Mitutoyo has developed a very complete product range for measuring rotationally symmetric workpieces to suit practically every application.

They are systems with exceptional geometric specifications, equipped with special centering and part leveling systems to minimize the incidence of part preparation on the final result. Manual, semi-automatic and automatic models available.

Manual

Roundtest RA10: The entry-level solution for simple form measuring tasks in a production environment. With large, clear display for performing operations and displaying the measurement results.

Roundtest RA120: The compact solution for precise, effective and easy form measurement in a production environment. With large, easilyreadable display for clear presentation of measurement results.

Roundtest RA120P: A compact device that is easy to operate, equipped with the same features as ROUNDTEST RA-120, for use in production. With added PC connectability and high-performance ROUNDPAK measuring and analysis software.

Semi-automatic

Roundtest RA 1600: Compact table-top instrument designed for high standards of measuring accuracy. Provides an ample measurement range suited to middle-sized compact and complex workpieces.

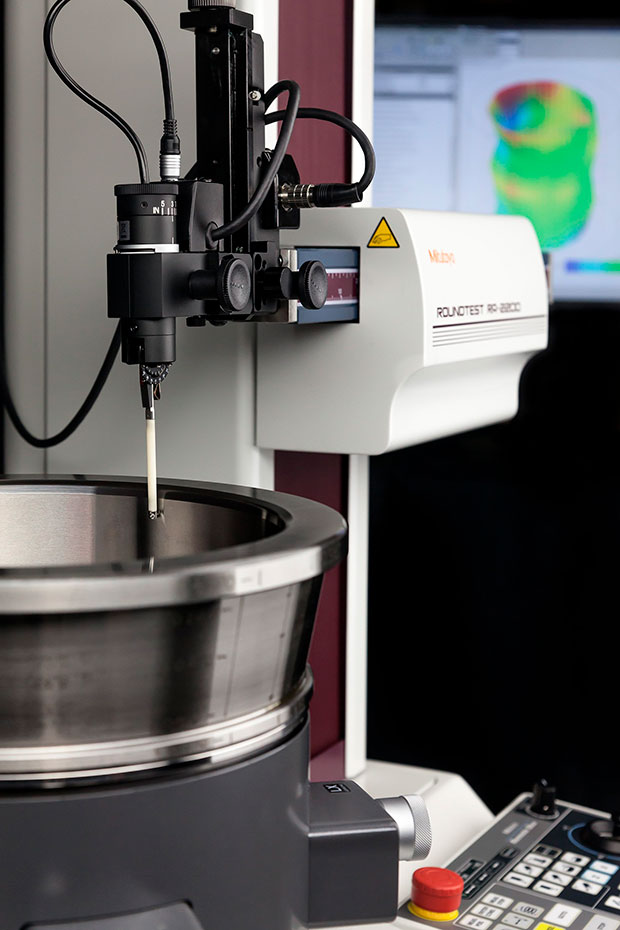

Roundtest RA2200: Table-top models for demanding, highly precise form measurement. Rapid manual centering and leveling of the workpiece on the digital adjustment table (DAT).

Automatic

Roundtest RA2200: Table-top models for demanding, highly precise form measurement. Rapid manual centering and leveling of the workpiece on the digital adjustment table (DAT).

Roundtest RA-H5200: Meets the highest standards in terms of positioning speed, fastest automatic centering and leveling, utmost precision, measuring volume and workpiece weight-handling capability. Automatically positionable, freely definable angle adjustment of the probe system.

Roundtest Extreme RA6000CNC: Fully automatic CNC form measuring instrument for heavy and precise parts with a maximum load capacity of 350 kg. Provides fast and accurate processing.

They use the ROUNDPAK software that offers full support for the control of the measurement system.

The software performs the following tasks:

Control all servo-powered axes

Center and level the turntable

Create part programs

Analyze deviations in form and position

Offer a wide range of graphic presentation options

Recalculate analyses

Analyze clashes

Create and store test reports

Related products and services

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

Inner roundness measurement for axis adjustment, flatness, cylindricality, incomplete circle roundness ... etc

Custom solution

We accompany you throughout the life of the project: definition of the project, installation, training, programming, user support, software updates, technical assistance, calibration and maintenance.

Sariki can communicate the roundness system with peripherals that will allow you to integrate the system even in the production process.

We can offer you solutions to automate your measurement system easily

Technical specifications

Manual

Roundtest RA10:

Rotational accuracy (0,04 + 0,0006H) µm

Roundtest RA120:

Rotational accuracy (0,04 + 0,0006H) µm

Roundtest RA120P:

Rotational accuracy (0,04 + 0,0006H) µm

Semi-automatic

Roundtest RA 1600:

Rotational accuracy (0,02 + 0,0006H) µm

Straightness of precision column (Z axis):0,2 µm / 100 mm

Roundtest RA2200:

Rotational accuracy (0,02 + 0,00035H) µm

Straightness of precision column (Z axis): 0,1 µm / 100 mm

Automatic

Roundtest RA2200CNC:

Rotational accuracy: (0,02 + 0,00035H) µm

Straightness of precision column (Z axis): 0,1 µm / 100 mm

Roundtest RA-H5200:

Rotational accuracy: (0,02 + 0,00035H) µm

Straightness of precision column (Z axis): 0,05 µm / 100 mm

Roundtest RA6000CNC:

Rotational accuracy: (0,05 + 0,0006H) µm

Straightness of precision column (Z axis): 1,5 µm / 1050 mm

Case study

Copreci has incorporated into its quality system a Measuring Machine of form and position errors RA-2200AH of Mitutoyo, with which they will meet the verification needs with the maximum precision in both the production stage and the engineering and design ones.