Sensor individual

Los modelos SV-C3200, SV-C4500 y SV-C4500CNC de Mitutoyo son sistemas que realizan dos secuencias de medición separadas para obtener la rugosidad y el perfil de tus piezas en un único software para obtener las mejores prestaciones de cada una de las tecnologías

SV-C3200: Combinación inteligente de dos sistemas completos para medición de perfil y análisis superficial exhaustivo.

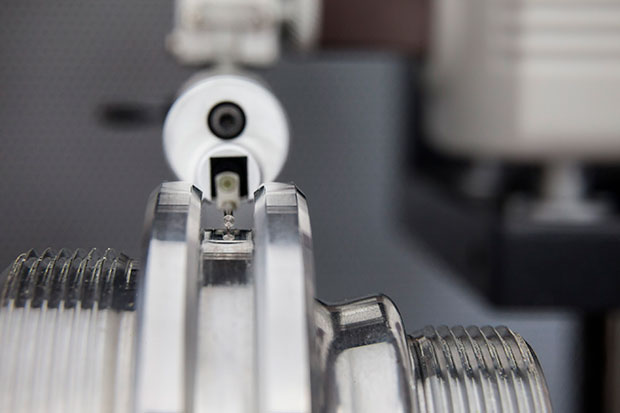

- Dos sensores individuales e intercambiables

- Captación lineal

- Ajuste de altura accionado por motor del eje Z

- Secuencia completamente automática de programas de medición

SV-C4500: Para requisitos particularmente exigentes en la medición de perfil en la sala de medición y en el laboratorio. Con sistema de palpador doble para la medición de perfil ascendente/descendente que posibilita la medición de diámetros.

- Dos sensores individuales e intercambiables

- Unidad de medición de perfil con palpador doble

- Ajuste de altura accionado por motor del eje Z

- Secuencia de programas de medición completamente automática

Todos los dispositivos utilizan el software Formtracepak de Mitutoyo. Se trata de un programa completo de medición de perfil y superficie de máxima eficiencia con opciones versátiles de evaluación y documentación.

Secuencias automáticas del programa de medición

Función bestfit para la secuencia de medición automática

Representación de resultados gráficos y numéricos

Representación gráfica del contorno del perfil o el perfil superficial

Construcción de geometrías de ayuda

Comparación de perfil

Rangos de tolerancia libremente definibles

Función de edición

Almacenamiento automático de los resultados de medición

Función de calibración automática

Archivo de datos de calibración

Productos y servicios relacionados

Junto a este equipo se pueden utilizar diferentes accesorios y software en función de las necesidades y usos que se le vayan a dar. Sariki le asesorará en todo momento sobre el complemento más adecuado a su caso, si así lo desea puede cosultarnos sin compromiso.

Aplicaciones

Medición de perfiles sobre cualquier tipo de pieza (mecanizada o no) evitando en la mayoría de los casos la necesidad de destruir la muestra para garantizar acceso. Medición de perfiles internos, medición de roscas, biseles, etc.

Medición y análisis de alta precisión de cualquier superficie. La medición en 3D abre nuevas posibilidades para el análisis de nuevos materiales y nuevas superficies derivadas de los nuevos procesos de fabricación (fabricación aditiva, etc…).

Solución personalizada SK/solutions

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario, actualización de software, asistencia técnica, calibración y mantenimiento anual.

Podemos ofrecerte soluciones para automatizar e integrar tu rugosímetro-perfilómetro de forma sencilla

Especificaciones técnicas

SV- C3200 / 4500

Transversal

Z2 300mm/500mm/700mm

Rango de medición

X 100/200mm; perfil Z1 60mm; rugosidad Z1 800 µm, 80 µm, 8 µm

Velocidad de medición

0,02-20 mm/s

SV-C4500CNC

Transversal

Z2 300mm/500mm

Rango de medición

X 200mm; Y 200mm; perfil Z1 60mm, Z2 300/500mm; rugosidad Z1 800 µm, 80 µm, 8 µm

Velocidad de medición

0,02-2 mm/s