SARIKI Precision Center is the high precision center located in Elgoibar (Gipuzkoa) that has the most innovative measurement technology and highly qualified staff to offer dimensional measurement services to the industrial sector.

With more than 300 square meters and a variety of equipment of different technologies, ranges and specifications, we can face any challenge that you propose, especially if it is high precision.

Types of services

- We make complete dimensional reports based on standards in all sectors (automotive, aerospace, machine tools, dental, health ...).

- Product and process capacity studies.

- Assistance in customer facilities (programming, measurement, advice and response to specific workloads).

- Measurement and adjustment of all types of fixturing tools.

- Tailored programming for customers in different software (SK/inspect, MCosmos, Metrolog, Geomagic, VG Studio, Inca, Gearpak, Formtracepack ...).

- Custom design and manufacturing of fixturing tools.

- 3D printing for inspection and reverse engineering.

- Non-destructive tests by microtomography and radiography.

- 3D scanning for different purposes.

- Point cloud capture

- STL generation

- STL alignment with CAD

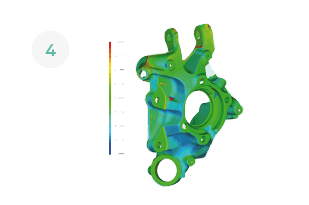

- Color mapping deviations

Why should you outsource our measurement service?

- Get your results on time. In times of production peaks, when measuring control machines are saturated, or you need professional support in your facilities, Sariki Precision Center’s measurement service can be your greatest ally. You will obtain your reports within the requested deadlines and with the highest reliability guaranteed, thus saving measurement times. What’s more, our metrologist technicians can provide you in-situ support whenever you need it.

- Proximity and professionality. In Sariki Precision Center we collaborate hand in hand with you so that you can achieve your objectives in terms of dimensional quality control. Our measurement service is characterized by its proximity and active collaboration with customers, since the contact is maintained from beginning to end, adapting to your most specific needs.

- A solution for almost any type of part. Thanks to the wide variety of technologies at our disposal, we can adapt to your most specific needs, and it won’t be necessary for you make a large investment in your facilities. In addition, our technician’s more than 20 years of experience and their versatility with different technologies, are synonymous of reliability and professionalism.

- Cost reduction. Outsourcing your measurements will give you a competitiveness advantage in the market. You will save on machinery maintenance costs, calibrations, amortizations and qualified personnel’s costs, thus increasing your department’s performance. In case that the measurement frequency in your facilities is not high, our metrology laboratory is a safe bet to ensure your part’s quality.

- Increase your department’s profitability. Our metrology service can become your best ally: when you need to carry out a set-up, urgent problems due to saturation, avoiding assembly problems, controlling parts before putting them in the machine… We support you in any of your problems, offering you the solution that best suits your needs, and increasing the profitability of your department.

Qualified and experienced staff

We have highly qualified staff with more than 20 years of experience measuring parts of all types of sectors, materials, shapes, precision requirements ... Our measurement technicians are versatile as they are experts in more than one technology, in order to guarantee appropriate working deadlines to the needs of our customers.

We are CERTIFIED under the EN 9100 quality standard, by AENOR INTERNACIONAL SAU, for the activity of providing parts measurement and inspection services for the aerospace sector.

We are registered in the OASIS platform (online information system of aerospace suppliers).

We present the technologies available at SARIKI PRECISION CENTER

Non-destructive tests with micro-tomography

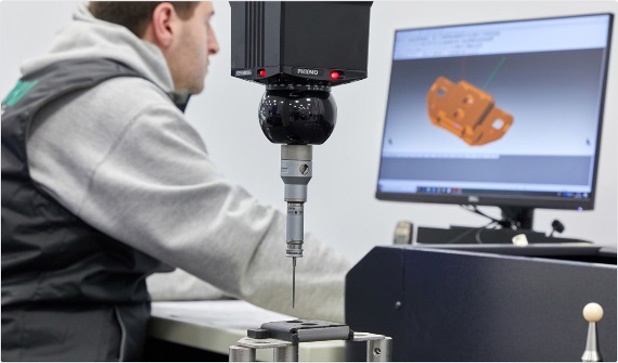

3D measurement with CMM

3D scanning

Contour measurement

Optical measurement

Optical measurement of turned parts

Form measurement

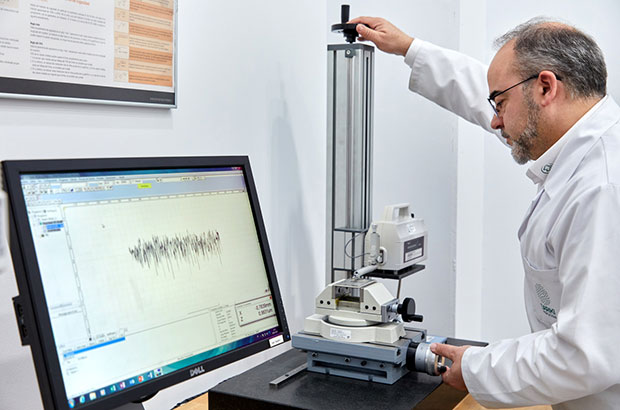

Roughness Measurement

Design and manufacture of fixturing tools