Metrology and the future of the electric vehicle

La automoción electrificada promete revolucionar la industria debido a sus emisiones (casi) nulas y la ausencia de ruido, en línea con las necesidades de la transición energética y los nuevos modelos de movilidad en todo el planeta.

Las ventas de vehículos eléctricos se han incrementado en el último año de forma importante. Las previsiones más optimistas auguran que en solo siete años circularán en el mundo entre 40 y 70 millones de coches eléctricos.

En Sariki tenemos la capacidad y responsabilidad para ayudar a los fabricantes del sector automoción en su reto de desarrollo y producción de vehículos eléctricos.

Ofrecemos a la industria un enfoque integrado, para mejorar, agilizar y simplificar el desarrollo de vehículos eléctricos y tecnologías de transición híbrida.

A continuación, os detallamos algunas de las múltiples aplicaciones que podemos abarcar con nuestras tecnologías de medición.

Unidad de control de potencia

- IGBT (Insulated Gate Bipolar Transistor)

- Varias dimensiones de los módulos de potencia

- Varias dimensiones del circuito semiconductor

- Inspección de roturas en piezas soldadas

- Altura del alambre de unión

- Carcasa del convertidor

- Varias dimensiones de la cabina de aluminio y estado superficial

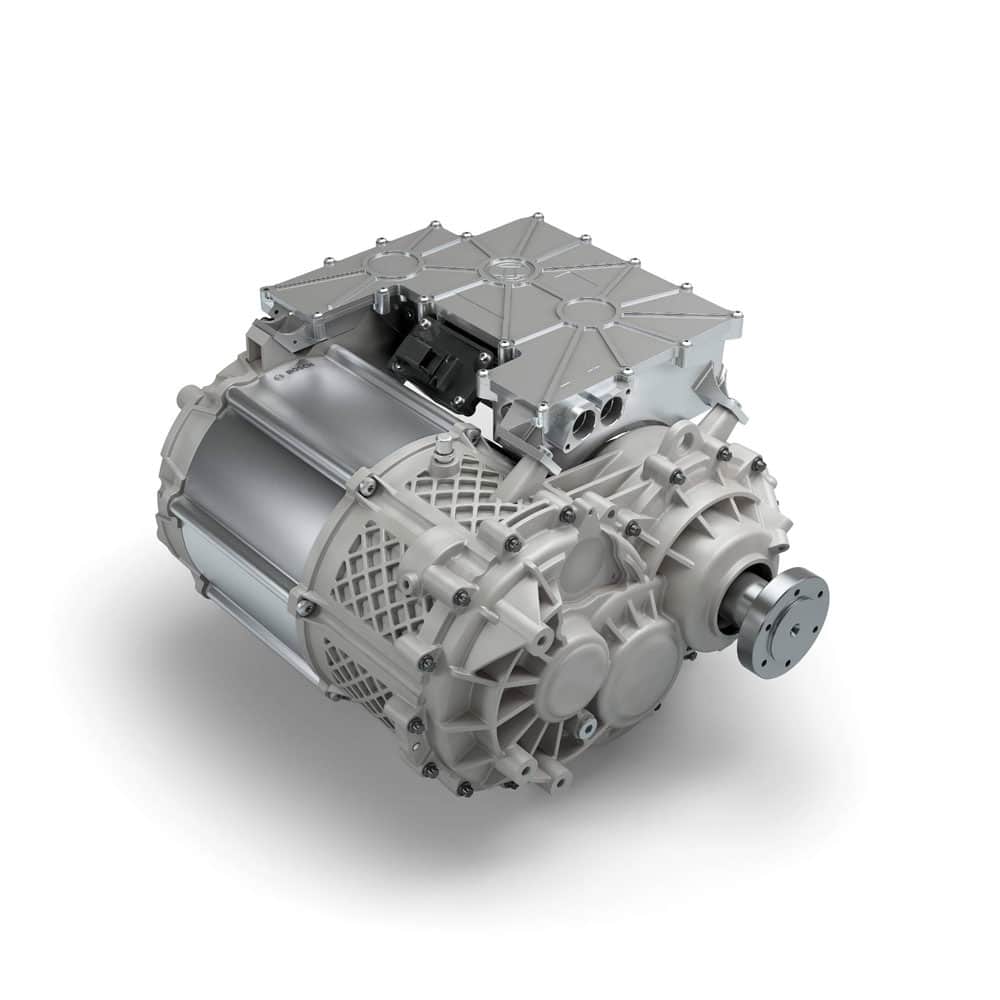

Motor

- Núcleo del motor

- Medicion dimensional de parte prensada no laminada

- Medición de varias tolerancias geométricas de parte prensada laminada

- Oscilación del eje de rotación

- Conmutador

- Gap adyacente periférico

- Cubierta

- Coaxialidad del rodamiento

- Bobina

- Diámetro exterior

- Verificación de forma

Batería

- Batería de iones de litio

- Medición dimensional y superficial de la carcasa

- Medición dimensional y superficial de la caja de la batería

- Medición del espesor y ancho del separador

- Observación de presencia o ausencia de contaminación

- Separador de pilas de combustible de hidrógeno / oxígeno

- Medición dimensional del molde de pieza y medición de forma.

- Medición de espesores del molde

- Medición del perfil del molde

Cargador de Batería

- Cargador de batería en vehículo

- Varias dimensiones de la cabina de aluminio

- Varias dimensiones de piezas prensadas

- Cuadratura y rugosidad de la clavija del conector

- Cargador rápido

- Varias dimensiones de los enchufes

- Estado superficial del terminal

- Varias dimensiones de los paneles

Piezas fabricadas en composite

La fabricación de piezas en materiales compuestos termoplásticos como sustitutos de los metales, permitirá diseñar coches más aerodinámicos, ligeros y con una mayor eficiencia energética. Ha habido un crecimiento exponencial de los composites de matriz polimérica pues su ligereza y resistencia ofrece un gran interés en el desarrollo del vehículo eléctrico.

Desde Sariki ofrecemos nuestro know how a los fabricantes para ayudarles a inspeccionar sus piezas durante el proceso productivo.

Mejora la inspección de los componentes compuestos mediante tomografía industrial

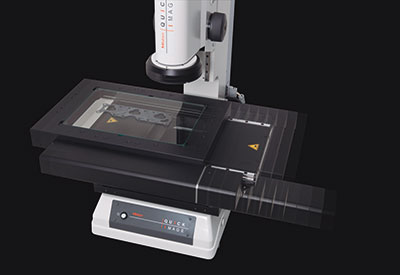

Estas son algunas de las tecnologías que pueden interesarte:

Diferentes tamaños y precisiones

Manual o con mesa motorizada

Rugosímetro, perfilómetro y redondez

Escáner láser y luz estructurada

Diferentes potencias y volúmenes de inspección

En Sariki estamos preparados para acompañarte en este apasionante reto. Cuenta con nosotros. Solicítanos más información rellenando el siguiente formulario.