Mitutoyo MISTAR

Medición 3D en línea compacta

La nueva solución de medición compacta para entornos de producción.

Garantiza un error máximo admisible de MPEE=(2.2+3L/1000)μm

Velocidad, fiabilidad y universalidad para tu control de producción

Solución ideal de medición 3D en línea: MISTAR

Diseñada para entorno productivo. La máquina de medición 3d MiSTAR te garantiza mediciones a alta velocidad y precisión incluso en sitios de mecanizado severos sin la necesidad de crear un entorno especial en el área de producción. Te ofrece una garantía de precisión bajo un amplio rango de temperaturas de 10°C a 40°C y requiere solo de una fuente de alimentación de 100 V CA. La flexibilidad en su instalación y el ahorro de espacio han reducido el área de instalación a aproximadamente el 70 por ciento de las MMC de tipo pórtico convencional.

Automatizable. MiSTAR 555 utiliza un diseño de estructura abierta (570 x 500 x 500mm) con un eje x en voladizo de tipo cantiléver lo que permite a los usuarios ubicar fácilmente una pieza para la medición desde tres direcciones: la parte delantera, trasera y derecha.

Realiza mediciones a alta velocidad. Máxima velocidad de desplazamiento 606mm/s. Aceleración 2695 mm/s

Rango de medición hasta 500mm.

Productos y servicios relacionados

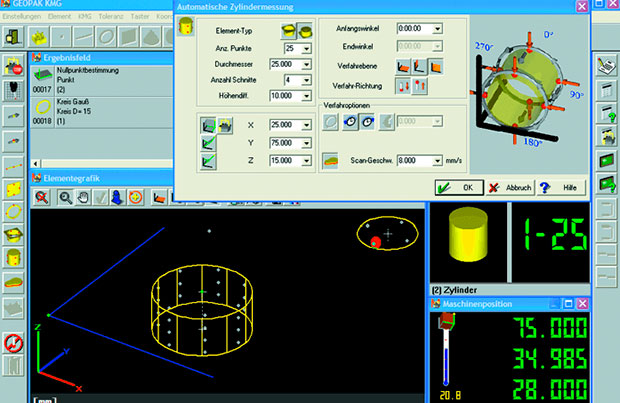

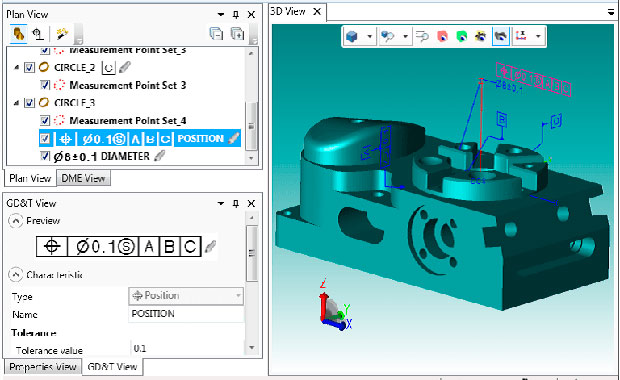

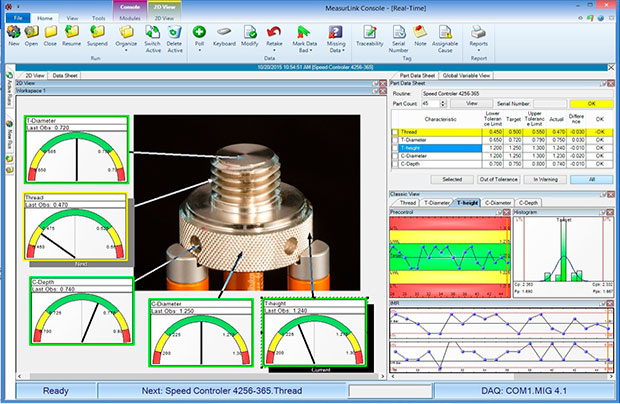

Junto a este equipo se pueden utilizar diferentes softwares en función de las necesidades y usos que le vayas a dar. Te asesoraremos en todo momento sobre el complemento más adecuado en tu caso si así lo deseas. Puedes consultarnos sin compromiso.

Aplicaciones

MiSTAR ha sido diseñada para la inspección de alta precisión de piezas del sector automoción, aeronáutico, salud, bienes de equipo, máquina herramienta, consumo…etc directamente en producción. El equipo es adecuado para la inspección de pieza mecanizada, estampación, inyección de plástico/aluminio, álabes de turbina, engranajes, moldes y matrices...hasta 500mm.

Sondas de medición

Tendrás un sistema versátil y flexible, al que podrás incorporar las siguientes sondas

TP 200

SP25M

Solución personalizada SK/solutions

Nuestro departamento de ingeniería puede personalizar e integrar la máquina de medición por coordenadas MACH V 9106 según tus requerimientos. Cuéntanos cuál es tu reto y desde Sariki te asesoraremos para identificar cual es la mejor solución para tu caso concreto.

SISTEMA DE CARGA

Puedes incorporar al equipo sistemas de carga manuales, semi-automáticos y automáticos.

SISTEMA DE CABINA

Identificamos el sistema de cabina que mejor se adapte a tu aplicación.

INTERACCIÓN CON LOS SISTEMAS DE GESTIÓN DE LA PRODUCCIÓN

Garantizamos la trazabilidad 100% del proceso integrando los datos de la MMC con tu sistema MES/ERP.

PROGRAMACIÓN PERSONALIZADA

Contamos con personal experto en programación y medición para la realización y puesta en marcha de los programas de medición de tus piezas.

PROYECTO LLAVE EN MANO

Si lo que buscas es un proyecto llave en mano puedes contar con nosotros. Colaboramos contigo desde la concepción de la idea y definición de condiciones del proyecto, aceptación previa, instalación en tu empresa, formación de usuarios y asistencia técnica y soporte durante toda la vida del proyecto.

Afrontamos los proyectos de integración desde una visión holística de las pautas de inspección a cumplir y apostamos por la hibridación de tecnologías. Somos capaces de desarrollar una solución de inspección que combine diferentes tecnologías: máquina tridimensional, rugosidad, visión artificial, etc.

Especificaciones técnicas

Rango de Medición

X 570mm

Y 500mm

Z 500mm

Precisión

(2.2 + 3L/1000)μm

de 18ºc a 22ºC

Resolución

0,0001mm

Velocidad máxima de accionamiento

Hasta 606mm/s

Aceleración máxima

Hasta 2.695 mm/s2

Rango de temperatura permitido

De 10ºC a 40ºC

Peso de la unidad principal

655 Kg.