ViciVision serie X

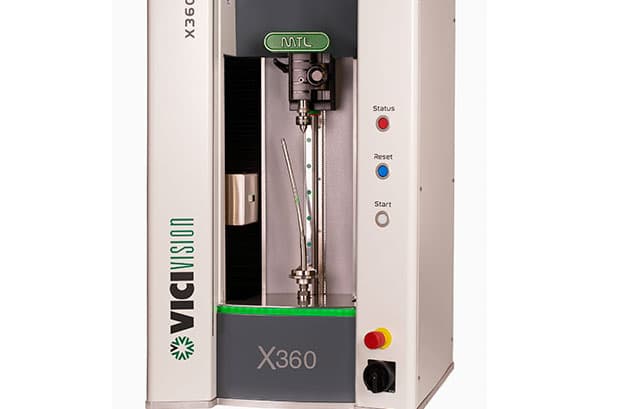

Máquinas de medición óptica diseñadas específicamente para componentes micro mecanizados.

Alta resolución, única en su categoría

La máquina actúa como una ampliadora, eliminando la falta de fiabilidad de las mediciones manuales y ofreciendo ventajas para obtener un control completamente automático, completo, rápido, preciso y objetivo.

Los sistemas de medición MTL X5 y MTL X10 toman las medidas en una imagen muy agrandada del elemento para obtener automáticamente longitudes, diámetros, ángulos, radios, biseles e hilos de hasta el más mínimo detalle.

Pensado para operarios de producción

Las máquinas de medición óptica MTL X5 y MTL X10 permiten a los operadores inspeccionar la producción sin conocimientos técnicos específicos de medición. El programa de la pieza se activa con un simple clic y decenas de medidas se toman en unos segundos, dando lugar a una retroalimentación positiva o negativa en el componente.

Almacenamiento de datos

El sistema almacena todos los datos con propósitos estadísticos y de trazabilidad, genera informes de medición y monitoriza la tendencia de fabricación, satisfaciendo las necesidades de la industria 4.0.

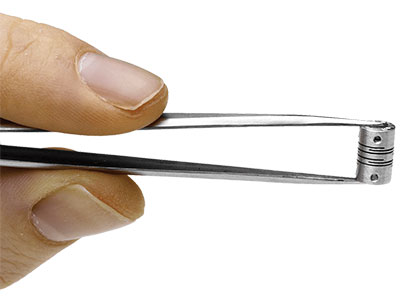

La solución ideal para la implantología dental y la tecnología biomédica

- La alta resolución, única en su categoría, detecta los detalles más pequeños

- Su diseño de acceso directo facilita la carga y descarga de incluso las piezas más difíciles de manipular.

- Sin aberturas ni huecos para que las piezas pequeñas se puedan recuperar fácilmente en el caso de que caigan durante su manipulación.

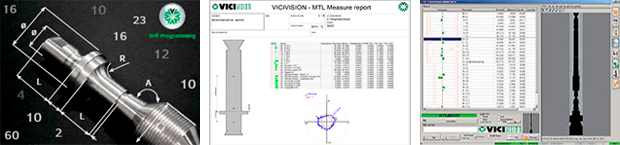

Software completo

Todas las mediciones son adquiridas de la imagen real de la pieza. Distancias, radios, ángulos, roscas y docenas de otras posibles soluciones, incluso comparación con DXF.

Características avanzadas

Los sistemas serie X de Vici Vision disponen de sistemas automáticos que ayudan al operador a detectar las medidas. Auto-programación, programación asistida paso a paso, programación manual avanzada, carga automática del programa de la pieza, además de la comparación con DXF.

Certificado de producción sin incrementar los costes

Visualiza el resultado de las mediciones en histogramas para la consulta inmediata. Obtén en la misma máquina el informe de las piezas medidas y gráficos de tendencia de medición con un simple clic.

Aplicaciones

Implantología dental, tecnología biomédica, industria relojera, aplicaciones micromecánicas y otros elementos extremadamente minúsculos.

Solución personalizada SK/solutions

Te ofrecemos una solución integral adecuada a tus necesidades. La experiencia nos dice que la colaboración con el cliente es la base del éxito de este tipo de proyectos y por ello desde el principio trabajamos conjuntamente para identificar cuáles son los requerimientos principales y proponerte la mejor solución.

Te acompañamos a lo largo de toda la vida del proyecto: definición del proyecto, instalación, formación, programación, soporte al usuario y asistencia técnica. Sariki está formado por un equipo de 60 personas altamente especializadas y con más de 34 años de experiencia en el sector de la metrología.

Especificaciones técnicas

| Rango de medición |

Tamaño máximo carga |

Precisión Ø - L |

Repetibilidad Ø - L |

Tamaño LxDxH mm |

Acometida eléctrica | |||

|---|---|---|---|---|---|---|---|---|

| Voltaje | Frecuencia | Potencia nominal | ||||||

| MTL X10 | 100x8 mm. | 270x90 mm. - 3 Kg. | 2 + D(mm)/100)] µm 5 + L(mm)/100)] µm |

0,4 µm / 3 µm | 560x660x860 mm. | 230 V. | 50/60 Hz. | 1,73 A. |

| MTL X5 | 100x16 mm. | |||||||